Výber optimálneho HPMC prášku pre vysokovýkonné lepidlá na dlaždice

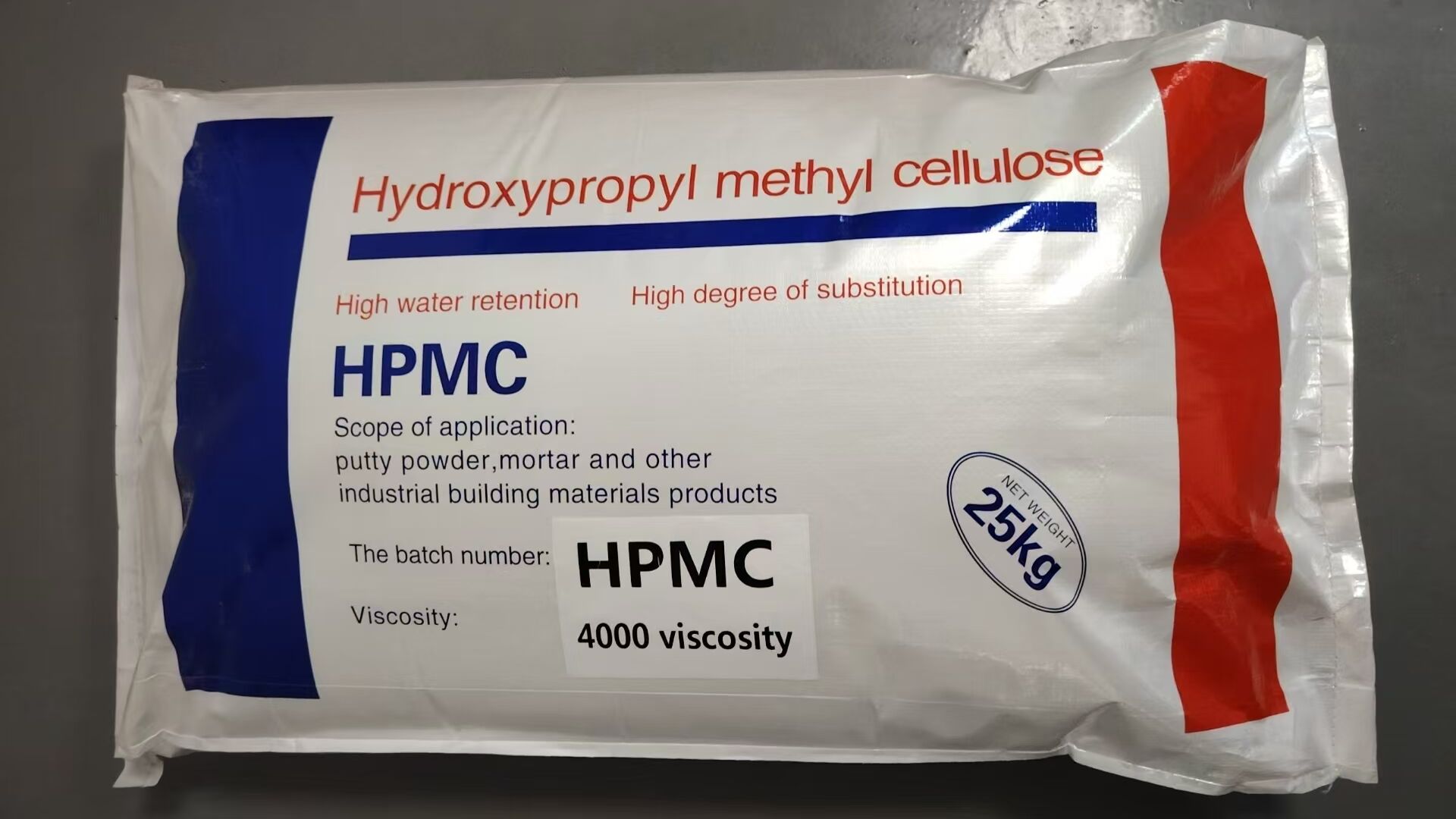

Kvalita a výkon lepidla na dlaždice výrazne závisí od výberu správneho Hydroxypropylmetylecelulóza (HPMC) prášok , kritická prísada, ktorá ovplyvňuje viaceré aspekty správania lepidla. Odborníci na stavbárstvo vedia, že nie všetky produkty HPMC prinášajú rovnaké výsledky, a preto je správny výber zásadný na dosiahnutie spoľahlivých a trvalých dlažobných inštalácií. Rôzne faktory, vrátane viskozitnej triedy, rozdelenia veľkosti častíc a úrovne purity, určujú, ako dobre prášok HPMC bude fungovať v konkrétnych formuláciách lepidla. Trh ponúka množstvo rôznych možností HPMC, pričom každá má jedinečné vlastnosti, ktoré ich činia vhodnými pre rôzne aplikačné scenáre. Od lepidla pre tenkú vrstvu keramickej dlažby až po maltu pre hrubú vrstvu prírodného kameňa, ideálny prášok HPMC musí presne zodpovedať určenému použitiu a požiadavkám na výkon lepidla. Porozumenie týmto kritériám výberu pomáha výrobcom a dodávateľom optimalizovať svoje formulácie lepidla za účelom dosiahnutia vynikajúcich výsledkov.

Kľúčové parametre na hodnotenie kvality HPMC

Vlastnosti viskozity a jej vplyv na výkon

Viskozitná trieda HPMC prášku predstavuje jednu z najdôležitejších kritérií výberu, ktorá priamo ovplyvňuje spracovateľnosť a aplikačné vlastnosti lepidla. Nízka viskozita HPMC (5 000–15 000 mPa·s) vytvára viac tekuté lepidlá, ideálne pre tenké vrstvy a malé dlaždice, kde je najvyššou prioritou ľahká nanositeľnosť. Stredné viskozitné triedy (15 000–60 000 mPa·s) ponúkajú vyvážený výkon pre bežné použitie v keramických lepidlách v rámci typických rezidenčných a komerčných projektov. Vysoká viskozita HPMC (vyššia ako 60 000 mPa·s) poskytuje vynikajúcu odolnosť proti odtékaniu a retenciu vody, čo je nevyhnutné pre veľkoformátové dlaždice a zvislé aplikácie. Metóda merania viskozity a koncentrácia použitá pri testovaní výrazne ovplyvňujú uvádzané hodnoty, čo sťažuje porovnávanie medzi dodávateľmi v prípade neexistencie štandardizovaného testovania. Niektoré pokročilé produkty HPMC ponúkajú modifikované viskozitné profily, ktoré zachovávajú spracovateľnosť a zároveň poskytujú vylepšené výkonové vlastnosti za konkrétnych podmienok.

Normy čistoty a chemického zloženia

Kvalitný HPMC prášok pre dlaždicové lepidlá musí spĺňať prísne požiadavky na čistotu, aby sa zabezpečila stála výkonnosť a predišlo sa možným problémom. Stupeň substitúcie (DS) metoxylových skupín a molárna substitúcia (MS) hydroxypropoxylových skupín určujú kľúčové vlastnosti, ako sú rozpustnosť, tepelná gelačná schopnosť a vodouudržiavacia kapacita. Nečistoty, ako napríklad zvyškové soli alebo vedľajšie produkty z výrobného procesu, môžu negatívne ovplyvniť výkon lepidla a jeho dlhodobú stabilitu. Dôveryhodní dodávatelia HPMC poskytujú podrobné certifikáty analýz, ktoré dokumentujú tieto chemické parametre pre každú várku. Potravinársky HPMC často presahuje požiadavky na čistotu pre stavebné aplikácie, ale nemusí ponúkať špecifické výkonné vlastnosti potrebné pre dlaždicové lepidlá. Výrobný proces a kvalita surovín výrazne ovplyvňujú finálnu čistotu HPMC a konzistenciu jeho výkonu.

Kritériá výberu HPMC špecifické pre aplikáciu

Priradenie vlastností HPMC k typom dlaždíc

Rôzne materiály dlaždíc vyžadujú špecifické vlastnosti HPMC, aby sa zabezpečila optimálna adhézia a dlhodobý výkon. Keramické dlaždice s nízkou vodnou absorpciou vyžadujú prášky HPMC, ktoré zlepšujú zmáčanie a kontakt s hladkým povrchom dlaždice. Pri inštalácii prírodného kameňa je výhodné použiť HPMC s vyššou retenciou vody, aby sa zabránilo predčasnému vyschnutiu a škvrneniu pórovitých materiálov. Veľkoformátové dlaždice vyžadujú modifikované typy HPMC, ktoré poskytujú predĺžený otvorený čas a vynikajúce vlastnosti proti odkvapovaniu. Lepidlá pre mozaikové dlaždice dosahujú najlepší výsledok s HPMC s nízkou viskozitou, ktorá umožňuje tenkú a rovnomernú vrstvu lepidla. Pri inštalácii sklenených dlaždíc je potrebné starostlivo vybrať HPMC, ktorá nevyvolá vizuálne nedokonalosti ani neovplyvní priepustnosť svetla. Pri výbere HPMC by ste mali tiež zohľadniť tepelnú rozťažnosť materiálu dlaždice, aby sa zabezpečila kompatibilita pri pohybe konštrukcie.

Klimatické a environmentálne faktory

Projektové prostredie zohráva kľúčovú úlohu pri určovaní najvhodnejšieho HPMC prášku pre dlaždicové lepidlá. V horúcich a suchých klimatických podmienkach je potrebné použiť HPMC s mimoriadnymi schopnosťami udržiavania vody, aby sa zabránilo rýchlej strate vlhkosti. Vo vlhkých prostrediach môžu byť potrebné modifikované typy HPMC, ktoré odolávajú nadmernému nasávaniu vlhkosti počas tuhnutia. Pri vonkajších aplikáciách je potrebné použiť HPMC, ktorý zachováva stabilitu pri pôsobení UV žiarenia a kolísaní teploty. Pri inštaláciách za studeného počasia sú výhodné prášky HPMC, ktoré urýchľujú hydratáciu a zároveň zabraňujú poškodeniu pri mrazivom rozmrazovaní. Projekty na vysokej nadmorskej výške sa stretávajú s jedinečnými výzvami, ktoré môžu vyžadovať špeciálne formulované produkty HPMC. Niektorí výrobcovia ponúkajú zmesi HPMC špecifické pre dané klimatické podmienky, ktoré sú navrhnuté tak, aby systémovo riešili tieto environmentálne premenné.

Požiadavky na technický výkon

Retencia vody a optimalizácia otvoreného času

Vynikajúca schopnosť retencie vody predstavuje jednu z najcennejších vlastností HPMC v dlaždicových lepidlách, ktorá priamo ovplyvňuje spracovateľnosť a hydratáciu cementu. Kvalitný HPMC prášok by mal udržať dostatočnú vlhkosť na rozhraní lepidla a dlaždice, aj keď sa aplikuje na vysoko vstrebávajúce podklady. Mechanizmus retencie vody HPMC zahŕňa chemické viazanie aj fyzikálne uzatvorenie molekúl vody v rámci jeho polymérnej matrice. Požiadavky na otvorený čas sa výrazne líšia v závislosti od veľkosti dlaždíc, pričom väčšie formáty vyžadujú dlhšie úpravy, ktoré zabezpečujú špecifické triedy HPMC. Niektoré pokročilé produkty HPMC ponúkajú profil uvoľňovania vody závislý na teplote, ktorý sa automaticky prispôsobuje vonkajším podmienkam. Testovanie retencie vody za reálnych podmienok aplikácie poskytuje najpresnejšie údaje o výkone pre porovnanie.

Spracovateľnosť a aplikačné vlastnosti

Ideálny prášok HPMC zlepšuje spracovateľnosť lepidla bez poškodenia iných výkonových vlastností, ako je adhézna pevnosť alebo čas tuhnutia. Hladká, rovnomerná konzistencia umožňuje ľahké miešanie a aplikáciu, pričom sa zachováva vhodná retencia v drážkach. Mazný účinok HPMC by mal znížiť odpor pri použití lžice bez toho, aby spôsoboval nadmerné prešmykovanie alebo odkvapovanie. Optimálna voľba HPMC vytvára lepidlá, ktoré sa ľahko odstraňujú zo zariadení, a zároveň majú vynikajúcu mokrú lepkavosť pre okamžitú podporu dlaždíc. Rýchlosť rozpúšťania HPMC ovplyvňuje efektívnosť miešania aj homogenitu hotového lepidla. Niektoré modifikované produkty HPMC ponúkajú zlepšené rozpustnosti, ktoré skracujú čas miešania a zamedzujú tvorbe hrudiek. Overenie v reálnych pracovných podmienkach je najlepším spôsobom, ako posúdiť skutočnú výkonnosť pri spracovaní.

Hodnotenie dodávateľa a zabezpečenie kvality

Výrobné štandardy a certifikácie

Dôveryhodní dodávatelia HPMC dodržiavajú prísne protokoly kontroly kvality počas výrobného procesu, aby zabezpečili stále dobrý výkon. Certifikát ISO potvrdzuje dodržiavanie medzinárodných noriem kvalitného riadenia výrobných procesov. Dodržiavanie nariadenia REACH preukazuje záväzok voči bezpečnosti chemických látok a environmentálnej zodpovednosti. Testovanie konzistencie medzi jednotlivými várkami zabezpečuje spoľahlivý výkon v priebehu viacerých výrobných cyklov. Komplexná technická podpora a dokumentácia produktu pomáhajú zákazníkom pri rozhodovaní o výbere. Niektorí dodávatelia ponúkajú špecializované riešenia HPMC prispôsobené konkrétnym formuláciám lepidla alebo požiadavkám na použitie. Pravidelné audity na zariadeniach dodávateľov poskytujú ďalšie záruky pravidiel kontroly kvality.

Technická podpora a vývoj produktu

Poprední dodávatelia HPMC poskytujú rozsiahlu technickú podporu, ktorá zákazníkom pomáha optimalizovať ich formulácie lepidiel. Aplikačné laboratóriá môžu vykonávať testovanie výkonnosti pomocou konkrétnych receptúr lepidiel a dlaždových materiálov. Výskumné a vývojové tímy neustále pracujú na vylepšovaní produktov HPMC a vývoji inovatívnych riešení. Podrobné technické údajové listy by mali zahŕňať všetky relevantné parametre výkonnosti a metódy testovania. Niektorí dodávatelia ponúkajú pomoc pri formulácii, ktorá pomáha dosiahnuť požadované vlastnosti lepidla. Schopnosť poskytovať prispôsobené riešenia HPMC pre špecifické aplikácie preukazuje technickú kompetenciu a zákaznícku orientáciu.

Často kladené otázky

Aká je ideálna viskozita HPMC pre lepidlá na keramické dlaždice?

Väčšina lepidiel na keramické dlaždice dosahuje dobré výsledky s HPMC strednej viskozity v rozsahu 15 000–40 000 mPa·s, čo zabezpečuje vyváženú spracovateľnosť a retenciu vody pre bežné inštalácie.

Ako ovplyvňuje veľkosť častíc HPMC výkon lepidla?

Jemnejšie HPMC prášky sa zvyčajne rýchlejšie rozpúšťajú a poskytujú hladší konzistenciu, zatiaľ čo hrubšie frakcie môžu ponúkať lepšiu retenciu vody a pomodlenejšie rozpúšťacie vlastnosti.

Môže HPMC zlepšiť lepiacu pevnosť?

Hoci HPMC primárne ovplyvňuje spracovateľnosť a retenciu vody, jeho úloha pri zabezpečovaní správnej hydratácie cementu nepriamo prispieva k dosiahnutiu optimálnej lepiacej pevnosti v utrvalených lepidlách.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ