Kľúčová úloha HPMC pri zvyšovaní výkonu lepidla pre dlaždice

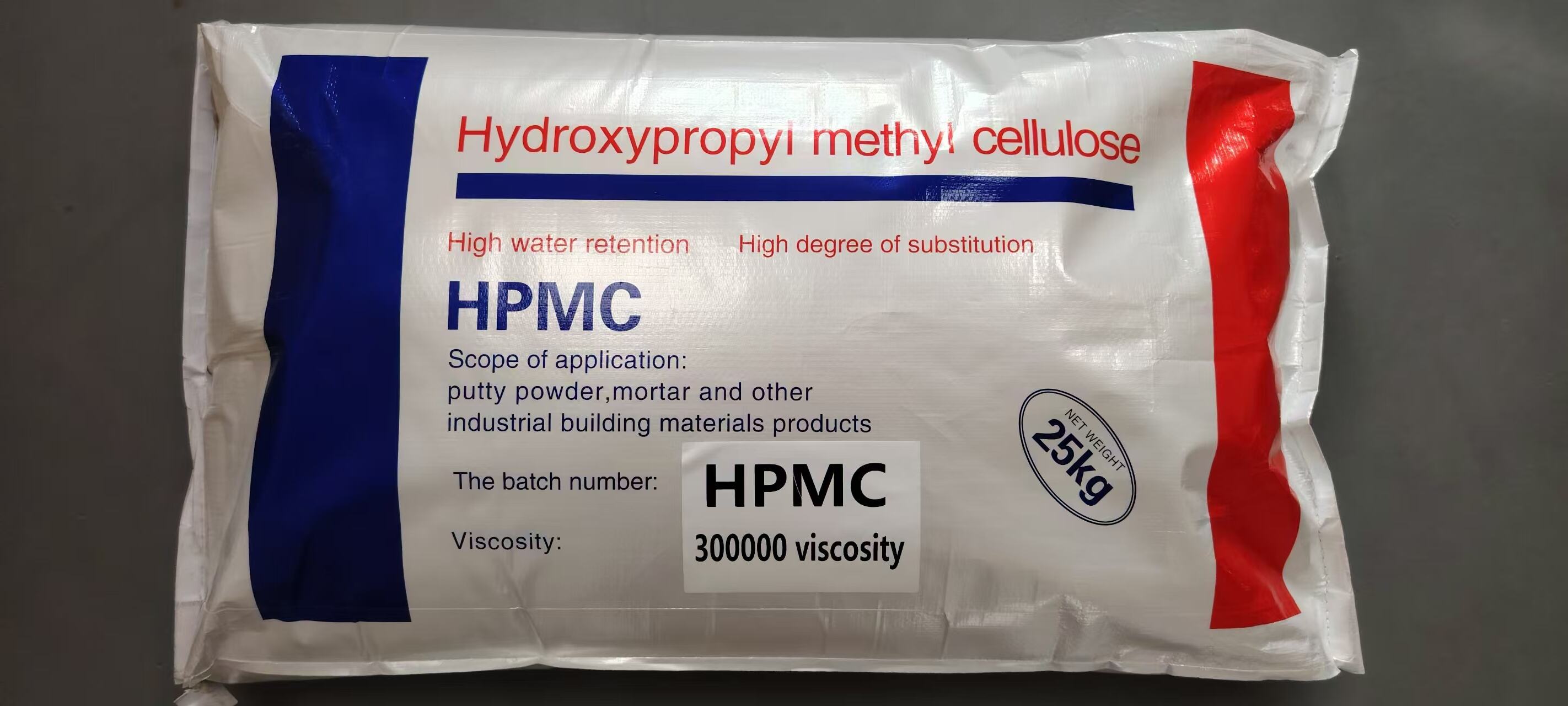

Moderné lepidlá pre dlaždice výrazne závisia od špeciálnych prísad, ktoré umožňujú dosiahnuť optimálny výkon, pričom Hydroxypropylmetylecelulóza (HPMC) vyčnieva ako jedna z najdôležitejších zložiek. Táto derivácia celulózového éteru zohráva zásadnú úlohu pri určovaní dvoch kľúčových vlastností lepidla na dlaždice: zdržiavanie vody a spracovateľnosť. Keď odborníci v oblasti stavebníctva vyžadujú od svojich materiálov čoraz vyšší výkon, pochopenie toho, ako HPMC ovplyvňuje tieto vlastnosti, získava na význame. Jedinečná molekulárna štruktúra HPMC umožňuje jej interagovať s molekulami vody a časticami cementu spôsobom, ktorý výrazne zlepšuje správanie lepidla počas aplikácie a tuhnutia. Rôzne triedy HPMC ponúkajú rôzne stupne týchto prospešných účinkov, čo správny výber činí nevyhnutným pre dosiahnutie požadovaných výsledkov. Od malých rodinných projektov až po rozsiahle komerčné inštalácie môže prítomnosť HPMC v lepidlách na dlaždice znamenať rozdiel medzi úspešnou, trvanlivou inštaláciou a inštaláciou, ktorá je postihnutá poruchami.

Ako HPMC zlepšuje zdržiavanie vody v lepidlách na dlaždice

Veda o schopnosti HPMC držať vodu

HPMC má vynikajúcu schopnosť udržiavať vodu vo formuláciách dlaždicového lepidla vďaka svojim hydrofilným polymérovým reťazcom, ktoré vytvárajú vodíkové väzby s molekulami vody. Po zmiešaní s vodou tieto polyméry vytvárajú želé podobnú sieť, ktorá postupne uvoľňuje vlhkosť počas procesu tuhnutia. Tento kontrolovaný mechanizmus uvoľňovania vody zabezpečuje, že cementové častice majú dostatočný čas na správne hydratovanie, čo vedie k silnejším konečným spojom. Vlastnosti HPMC na udržiavanie vody sú obzvlášť cenné v horúcich alebo suchých podmienkach, kde by rýchle odparovanie vlhkosti mohlo inak ohroziť výkon lepidla. Rôzne molekulové hmotnosti HPMC ponúkajú odlišné schopnosti udržiavania vody, čo umožňuje formulátorom prispôsobiť produkty konkrétnym klimatickým podmienkam. Kvalitný HPMC si udržiava svoje vlastnosti udržiavania vody aj vtedy, keď sú lepidlá aplikované na pórovité substráty, ktoré by normálne rýchlo absorbovali vlhkosť.

Praktické výhody zvýšeného udržiavania vody

Zlepšená retencia vody zabezpečená HPMC sa priamo prejavuje niekoľkými praktickými výhodami na stavbe. Predĺžená otvorená doba umožňuje inštalátorom upraviť pozíciu dlaždíc bez spiechania, čím sa znižuje odpad materiálu a zlepšuje sa kvalita inštalácie. Úplné hydratovanie cementu zabezpečené HPMC má za následok vyššiu tlakovú a ohybovú pevnosť vytvrdenej lepiacej zmesi. Znížená skrutosť počas schnutia minimalizuje namáhanie dlaždicových spojov a zabraňuje vzniku trhlín alebo dutín pod dlaždicami. Stále vlhké prostredie vytvorené HPMC podporuje rovnomerné vytvrdzovanie po celej hrúbke lepiacej vrstvy, bez ohľadu na pórozosť podkladu. Tieto výhody sú obzvlášť zrejmé pri práci s veľkoformátovými dlaždicami alebo prírodným kameňom, ktoré vyžadujú dlhšiu úpravnú dobu. Správna retencia vody tiež zabraňuje vzniku slabých miest v lepiacej zmesi, ktoré by mohli v budúcnosti viesť k poškodeniu dlaždíc.

Vplyv HPMC na spracovateľnosť lepiacej zmesi na dlaždice

Úprava reologických vlastností pre lepšiu aplikáciu

HPMC výrazne zlepšuje spracovateľnosť dlaždicových lepidiel tým, že upravuje ich reologické vlastnosti a vytvára ideálnu rovnováhu medzi viskozitou a tokom. Polymerové reťazce v HPMC interagujú s ďalšími zložkami lepidla a vytvárajú hladké, súdržné zmesi, ktoré sa ľahko nanášajú a zároveň odolávajú odkvapkávaniu. Táto zlepšená spracovateľnosť umožňuje vytvárať rovnomerné zárezy počas nanášania lepidla hrebľom, čo zabezpečuje správnu úroveň pokrytia a pevnosť spojenia. Mazný účinok HPMC znižuje úsilie potrebné na aplikáciu, pričom udržiava dostatočnú hustotu na podporu hmotnosti dlaždíc počas ich umiestňovania. Rôzne stupne viskozity HPMC umožňujú vývojárom vytvárať produkty od hrubovrstvých maltov až po tenké, samonivelačné lepidlá. Teplotná stabilita HPMC pomáha udržať rovnomernú spracovateľnosť v rôznych klimatických podmienkach, ktoré by inak mohli ovplyvniť výkon lepidla.

Zvyšovanie efektívnosti a výsledkov aplikácie

Zlepšená spracovateľnosť, ktorú zabezpečuje HPMC, má za následok hmatateľné výhody počas procesov pokládky dlažby. Inštalatéri môžu dosiahnuť rovnomernejšie pokrytie lepidla s menším úsilím, čím sa znižuje únava a zvyšuje produktivita. Vlastnosti proti odkvapkávaniu udržiavajú aplikácie vo zvislej polohe na mieste, čo je kľúčové pre dlažbu stien a inštalácie veľkého formátu. Hladká a rovnomerná konzistencia minimalizuje zachytávanie vzduchu počas aplikácie a tým zabraňuje vzniku slabých miest v lepiacej vrstve. Jednoduché čistenie nástrojov ušetrí čas medzi jednotlivými aplikáciami a znižuje odpad materiálu na nástrojoch. Zlepšená rozlisovateľnosť umožňuje vytvárať tenšie, efektívnejšie lepiace vrstvy bez toho, aby sa obetovával výkon. Tieto vylepšenia spracovateľnosti sa ukazujú ako obzvlášť cenné pri práci s náročnými dlaždicovými materiálmi alebo zložitými inštaláciou, ktoré vyžadujú presnosť.

Výber správneho HPMC pre optimálny výkon

Pochopenie rozdielov v viskozitných triedach

Prevádzkové vlastnosti HPMC v dlaždicových lepidlách sa výrazne líšia v závislosti od vybranej viskozitnej triedy, čo robí správnu voľbu kľúčovou. Triedy HPMC s nižšou viskozitou (zvyčajne pod 15 000 mPa·s) poskytujú vynikajúcu spracovateľnosť a sú ideálne pre tenké vrstvy, kde je potrebná dobrá roztierateľnosť. Stredné viskozitné triedy (15 000–60 000 mPa·s) ponúkajú rovnováhu medzi spracovateľnosťou a odolnosťou proti odtékaniu pre všeobecné použitie. Vysoké viskozitné triedy (nad 60 000 mPa·s) zabezpečujú vynikajúcu retenciu vody a vlastnosti proti odtiekaniu pre hrubé vrstvy alebo vertikálne aplikácie. Molekulová hmotnosť distribúcie v rámci každej triedy tiež ovplyvňuje výkon, pričom užšie distribúcie poskytujú konzistentnejšie výsledky. Niektoré špeciálne produkty HPMC kombinujú viacero viskozitných vlastností na riešenie konkrétnych výziev pri aplikáciách.

Prispôsobenie vlastností HPMC požiadavkám aplikácie

Výber vhodnejšej triedy HPMC vyžaduje dôkladné zváženie niekoľkých projektovo špecifických faktorov. Inštalácie dlažby veľkého formátu zvyčajne využívajú HPMC vyššej viskozity, ktorá zabezpečuje predĺžený otvorený čas a lepšiu odolnosť proti odtékaniu. Systémy s rýchlym tuhnutím môžu využívať modifikované triedy HPMC, ktoré udržiavajú spracovateľnosť a zároveň umožňujú rýchlejší vývoj pevnosti. Exteriérové aplikácie často vyžadujú HPMC s vylepšenou schopnosťou zadržiavať vodu, aby sa zabránilo vysúšaniu vetrom a slnečným žiarením. Klimatické podmienky výrazne ovplyvňujú výber HPMC, pričom horúči vyžaduje vyššiu schopnosť zadržiavania vody. Porozita podkladu tiež zohráva úlohu, keďže viac vstrebávajúce povrchy potrebujú lepidlá formulované s HPMC, ktorá udržiava vlhkosť na lepiacej línii. Pochopenie týchto premenných zabezpečuje optimálny výkon lepidla v každej jedinečnej situácii.

Technické aspekty pri formulácii HPMC

Interakcia s ďalšími zložkami lepidla

HPMC nefunguje izolovane, ale interaguje s rôznymi inými zložkami v zmesiach na lepenie dlaždíc, čím vytvára vlastnosti konečného produktu. Celulózový éter pôsobí synergicky s práškovými polymérmi, ktoré sa môžu znovu rozpustiť, a zvyšuje tak pružnosť aj pevnosť v lepení. HPMC ovplyvňuje kinetiku hydratácie cementu, čo má vplyv na dobu tuhnutia aj na vývoj konečnej pevnosti. Prítomnosť HPMC môže meniť spôsob pôsobenia iných prísad, ako napríklad spomaľovačov alebo urýchľovačov. Niektoré plnivá a zriedzadlá môžu vyžadovať konkrétne typy HPMC, aby sa zabránilo segregácii alebo problémom so spotrebou vody. Moderné produkty HPMC sú často navrhnuté tak, aby poskytovali optimálne výsledky pri bežných typoch cementu používaných v lepidlách na dlaždice. Tieto interakcie znamenajú, že pri vývoji alebo úprave zloženia lepidla je nevyhnutná komplexná skúšobná previerka.

Kontrola kvality a faktory konzistencie

Výkon HPMC v dlaždicových lepidlách závisí výrazne od dodržiavania prísnych noriem kontroly kvality počas výroby. Konzistencia molekulovej hmotnosti medzi jednotlivými várkami zabezpečuje predvídateľné udržiavanie vody a spracovateľnosť. Správne rozdelenie veľkosti častíc ovplyvňuje rýchlosť rozpúšťania aj konečný výkon lepidla po zmiešaní. Kontrola obsahu vlhkosti zabraňuje chomádeniu a zabezpečuje rovnomerné dispergovanie počas miešania. Úroveň čistoty ovplyvňuje nielen výkon, ale aj dlhodobú stabilitu lepidla. Dôveryhodní dodávatelia HPMC uplatňujú prísne testovacie protokoly, aby zaručili stále dodržiavanie týchto kvalitných parametrov. Tieto faktory kvality sú obzvlášť dôležité pre výrobcov lepidiel, ktoré musia spĺňať medzinárodné štandardy výkonu.

Často kladené otázky

Ako koncentrácia HPMC ovplyvňuje výkon lepidla?

Zvyšovanie koncentrácie HPMC zvyčajne zlepšuje retenciu vody a viskozitu, ale vyžaduje starostlivú rovnováhu, aby sa predišlo nadmernému zahusťovaniu alebo oneskorenému času tuhnutia v aditívnej formulácii.

Môže sa HPMC použiť v rýchlotuhnúcich dlaždicových lepidlách?

Sú k dispozícii špeciálne značky HPMC, ktoré udržiavajú prospešné vlastnosti a zároveň umožňujú skrátený čas tuhnutia vyžadovaný v rýchlotuhnúcich systémoch lepidla.

Má HPMC vplyv na konečnú pevnosť spoja dlaždicových lepidiel?

Hoci HPMC primárne ovplyvňuje spracovateľnosť a retenciu vody, jej úloha pri zabezpečovaní správneho hydratovania cementu nepriamo prispieva k dosiahnutiu optimálnej pevnosti spoja v utrvalom lepidle.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ