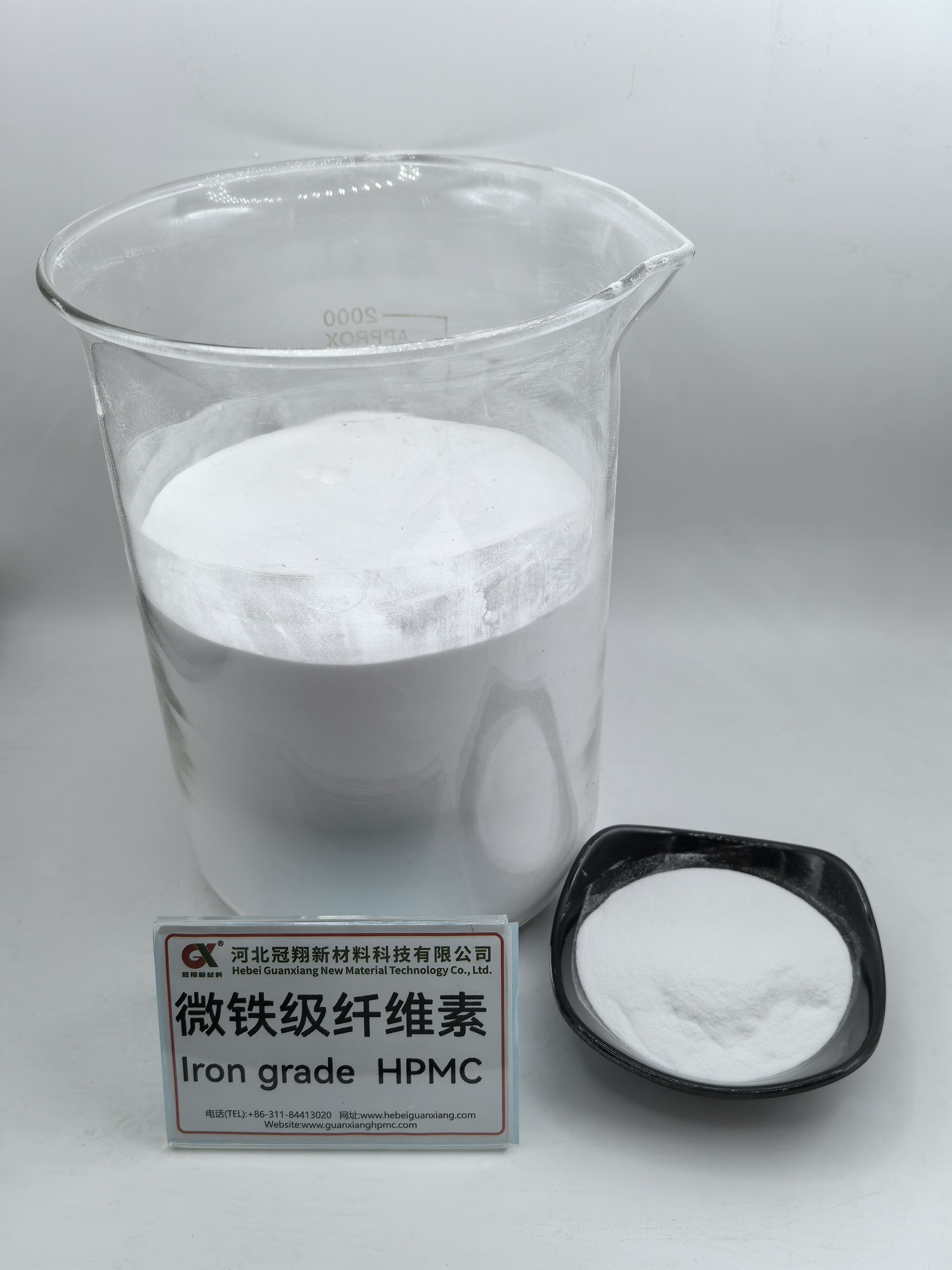

hpmc micro iron grade hpmc

HPMC micro iron grade HPMC (Hydroxypropyl Methylcellulose) represents a specialized formulation designed specifically for iron-fortified applications. This advanced grade of HPMC serves as a crucial binding and film-forming agent in pharmaceutical and nutritional supplement manufacturing. The micro iron grade variation features precisely controlled particle size distribution and optimized molecular weight, ensuring consistent performance in iron supplement formulations. It demonstrates exceptional stability when combined with iron compounds, preventing unwanted interactions and maintaining the integrity of the final product. This grade exhibits superior film-forming properties, providing excellent coating capabilities for iron-containing tablets and capsules. The material's unique chemistry allows for controlled release properties, enabling manufacturers to develop products with specific dissolution profiles. Additionally, it offers enhanced moisture resistance, which is crucial for protecting iron supplements from environmental factors that could compromise their efficacy. The grade is specifically engineered to maintain its functionality even in the presence of iron ions, which typically can interfere with standard HPMC grades.