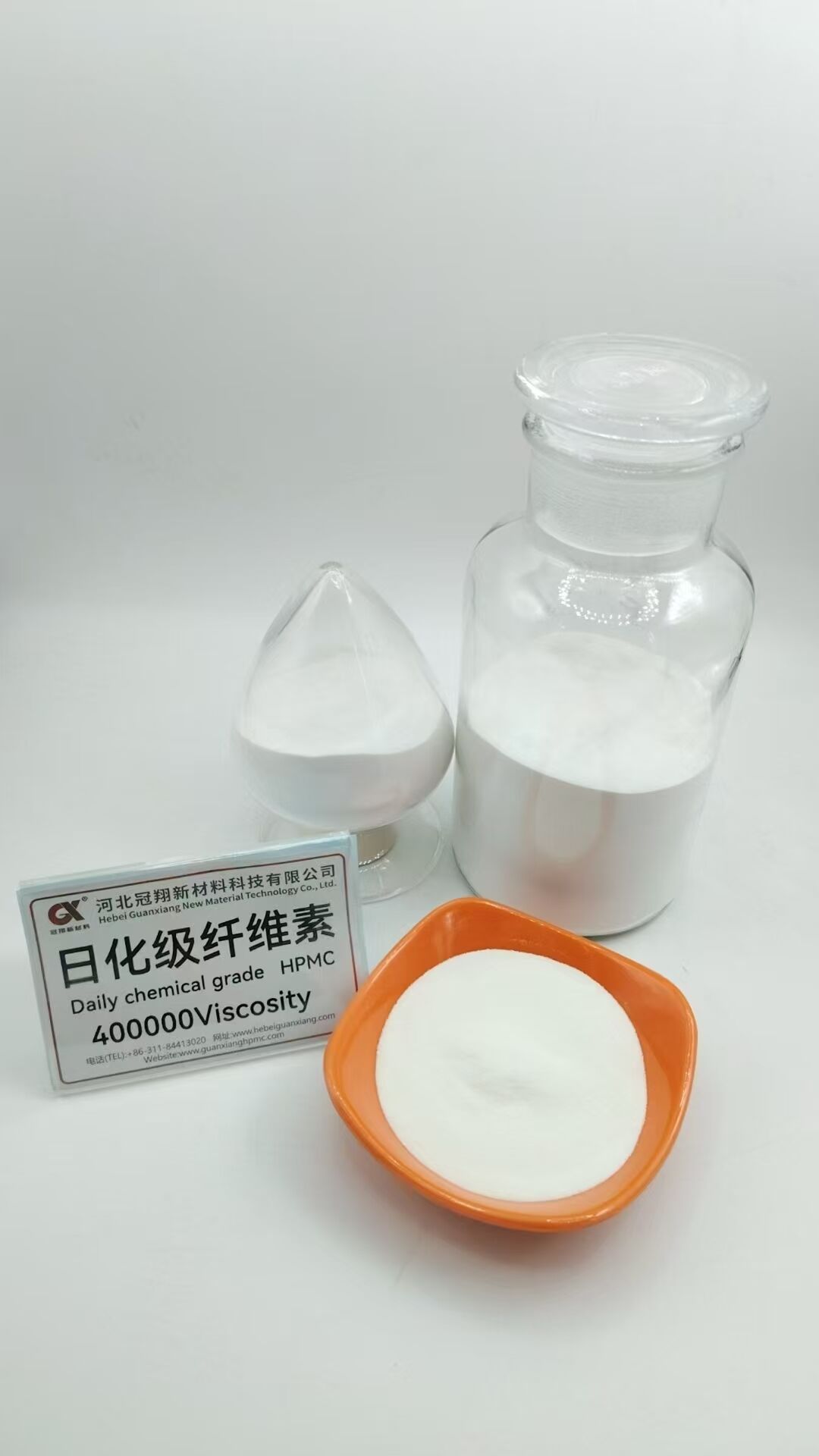

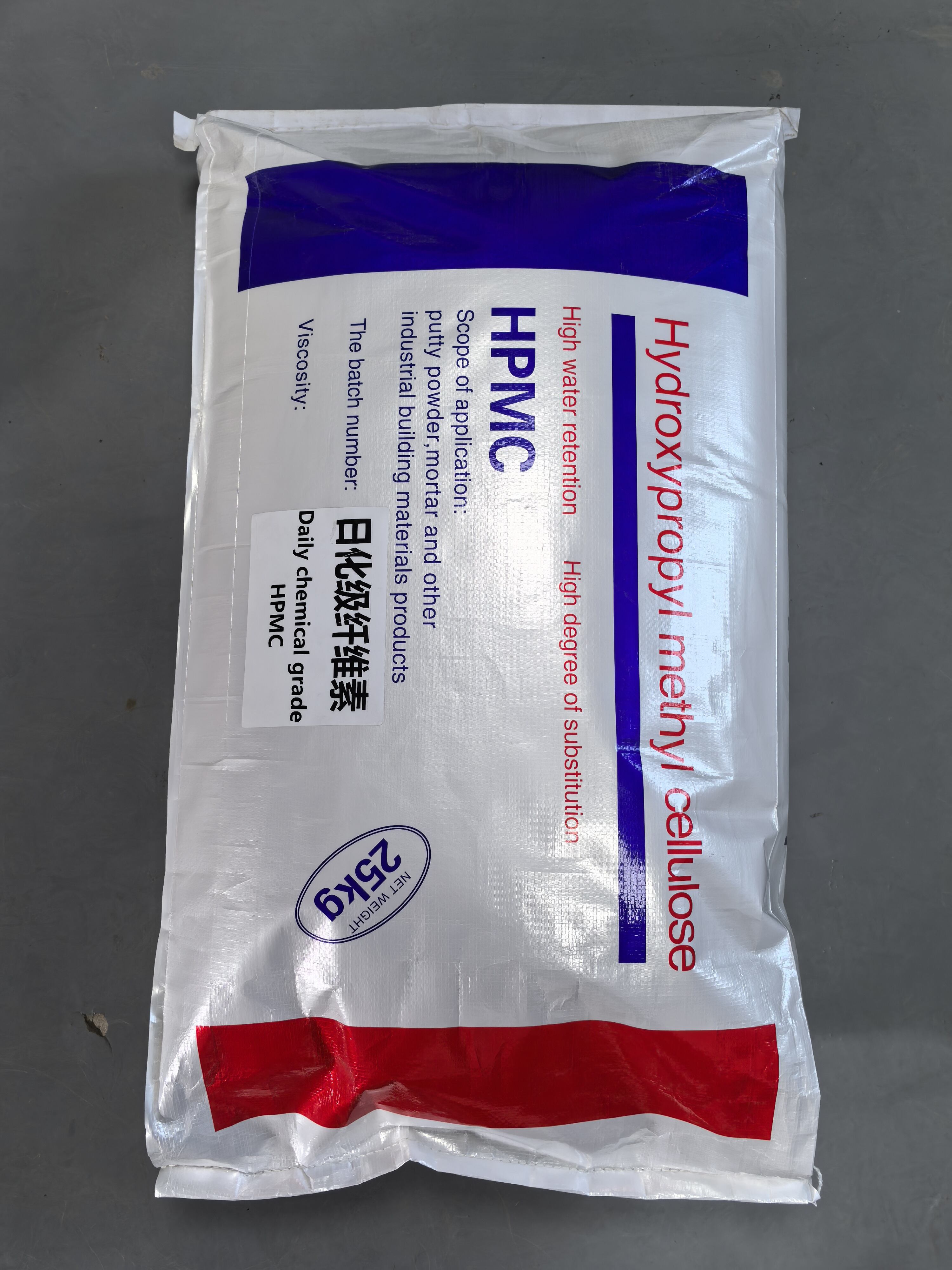

chemical hpmc

Hydroxypropyl methylcellulose (HPMC) is a versatile semi-synthetic polymer derived from cellulose. This remarkable compound serves as a crucial ingredient in various industries, combining excellent film-forming capabilities with superior water solubility. HPMC functions as an effective thickener, binder, emulsifier, and stabilizer in numerous applications. In pharmaceutical applications, HPMC plays a vital role in controlled-release drug delivery systems, serving as a matrix for tablets and capsules. Its unique properties allow for precise control over drug release rates, enhancing therapeutic effectiveness. In the construction industry, HPMC acts as a critical additive in cement-based materials, improving workability, water retention, and adhesion properties. The food industry utilizes HPMC as a food additive, where it functions as a thickening agent and stabilizer in various products. Its ability to form temperature-responsive gels makes it particularly valuable in food applications. Additionally, HPMC finds extensive use in personal care products, serving as a protective colloid and viscosity modifier. The compound's exceptional stability across various pH levels and temperatures, combined with its non-toxic nature, makes it an ideal choice for multiple applications. Its film-forming properties also make it valuable in coating applications, providing excellent barrier properties and controlled permeability.