Applicationes Industriae Constructionis HPMC

Melioratio Materialium a Cemento Factorum per Hydroxypropyl Methylcellulosam

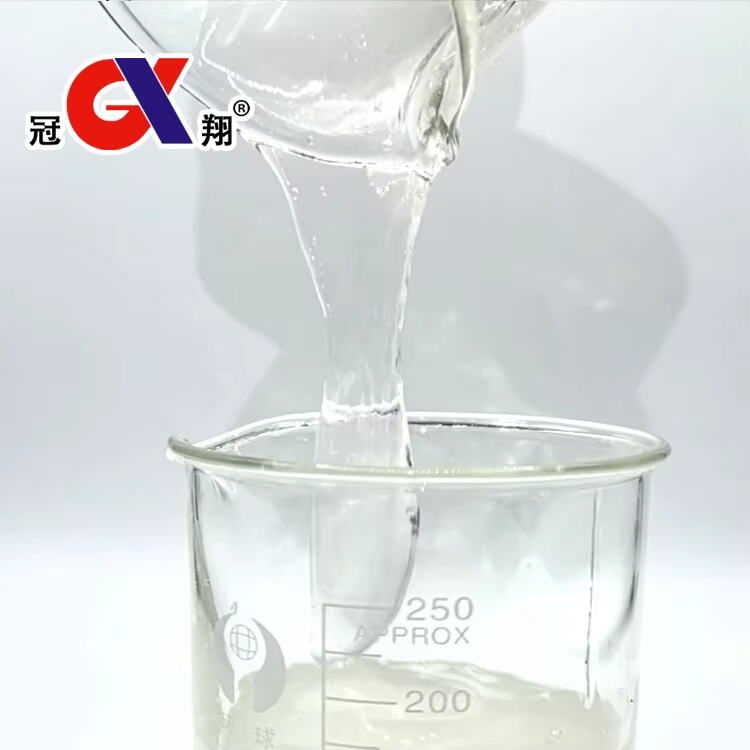

Dum discimus quomodo Hydroxypropylis Methylcellulosa, sive HPMC, in materia cementicia operatur, omnem differentiam facit ad melioranda aedificandi genera. Quod invenimus est HPMC hanc rem esse ut materiae tractabiliorem et cohaerentiorem fiant, ita ut meliores superficies parietum atque facies obtineantur. Experientiae docent cum in creta coniuncta sit, HPMC diutius aquam retinet quam ceteroquin. Hoc refert quia cemento tempus opus est ad perfecte hydratare priusquam solidescat. Quod evenit? Strutcturae validiores quae diutius durant sine ruptura aut exfoliatione. Est etiam aliud emolumentum. HPMC veluti scutum quoddam circum particulas in mistura agit, easque uniformiter dispersas retinet. Haec aequalis distributio est quae mixtiones cementi a segregando interdum durante applicatione prohibet, quod exactores molestum esse censent.

HPMC in Adhesivis Ceramicae et Compositionibus Mortarii

Hydroxypropyl Methylcellulose, quod vulgo HPMC dicitur, multum refert in adiuvandis mixtis tectorum et operis latericii. Cum his productis permixta, HPMC mirifice adiuvat ad fortificandam adhaesionem tectorum ad superficiem cui applicatur, qua re aedificia diutius durant sine problematibus. Praeclarum HPMC praeterea est quod aquam multo melius retinet quam aliae additamenta. Hoc operariis copiam temporis dat ad opus cum adiuvando peragendum, quod in magnis operibus valde refert. Praeterea, cum HPMC in compositione adsit, tecta post collocationem multo minus probabiles sunt ut moveantur aut labantur. Hoc valde refert cum in parietibus operatur, quia tecta aliter solent labi deorsum, qua re difficultates et materiae perditi fiant.

HPMC in Fabricatione Medicamentorum

Capsulae Hydroxypropyl Methylcellulosae ad Dandi Medicamenti

Hydroxypropyl-methylcellulose, seu HPMC breviter, in fabricatione capsularum vegetarianarum ad medicamenta vehenda magnum momentum nunc habet. E cellulosa derivatum, hoc substituit bene capsulas gelatinosas vulgares, quas multae personae vitant quod ingredientes animalia continent. Investigatio docet, cum medicamenta in capsulis HPMC dantur, melius in corpore adsorbentur, quod hos formae medicinae liberationis tardae aptos reddit. Cur? Quia HPMC gelidum formatur cum humore contactum habet, et haec proprietas regulet, quam celeriter medicamentum in systema liberetur. Praeterea, fabricatores capsulas sine ulla ingredientia animalica omnino fieri possunt, quod optatis consummatorum respondet. Hac in re pertractata, societates pharmaceuticae ad eas personas pervenire possunt, quae praeferrunt solutiones ex plantis ortas, sive propter convictiones religiosas, curas sanitarias, sive tantum electionem personalem.

Capsulae Vegetarianae et Formulationes Sine Additamentis

Quod facit Hydroxypropyl Methylcellulosum (HPMC) tam interessans ad pharmae industria est quomodo iuvat creare producta cum purioribus notis. Homines scire volunt quid in medicamenta sua ingreditur, et magna translatio facta est ad ingredientia naturalia trans omnes sectores. Capsulae vegetarianae e HPMC factae directe resolvunt hanc necessitatem, quod non continent additamenta synthetica aut materiales animalium. Analystae mercati animadvertunt companias quae ad formulae HPMC vertunt se saepe eminere in mercatis completis quia consummatores appretiant notitias simplices. Cum allergiis et cibariis prohibitionibus frequentioribus esse quam unquam antea, HPMC munere fungitur ut homines tamen medicamenta necessaria adipiscantur, quaecumque sunt eorum cibariae electiones. Crescens popularitas plantarum vitam ducendi significat manufactores qui HPMC in processibus suis includunt melius positi esse ut satisfaciunt hanc segmentum crescentem consummatorum sanitatis.

Usus Hydroxypropyl Methylcellulosae in industria cibaria

HPMC ut stabilisator in panificatione et lactariis PRODUCTS

In industria cibaria crescit interest in Hydroxypropyl Methylcellulosa (vel HPMC) propter id quod ad stabilitatem productorum conferre potest, praesertim in rebus coctis et lacteis. Cum ad misturas panificii additur, haec res adiuvat retinendum humiditatem, ut producta diutius in tabernis integra manent. Panifices hoc amant, quia panes, placentas et pastas citius non siccant sine his conservativis artificialibus. Aliud mirabile de HPMC est quod mellem in iis rebus, ut iaucundum et lactis substituta repraesentat, tamen eam pinguedinem et mollitiem retinet quam homines exspectant. Hoc manufactores permittit leviorem versionem productorum creare nihilominus sapore aquoso aut fastidioso, quod in hodierno mercato multum refert, ubi homines optiones salubriores quaerunt, sed tamen bonum saporem appetunt. Investigatio industriae saepius ostendit cibos HPMC continentes melius saporem habere apud plures consumptores, qui eam satietatem oris praebent quem omnes quaerunt. Haec omnia praerogativa sunt cur plures coporationes ad HPMC convertant dum conantur facere sua producta simul iucundiora et salubriora.

Coating Alimentaria et Emulsificatores Vegetabilis

HPMC excellit ut emulsificans et materia tecturae ex planta quae mirabiliter in productione ciborum operatur. Quando additur rebus ut salsis vel condimentis insalatae, praebet his productis saporosum et molle tactum oris quem homines amant, sine ulla sensatione artificiosa. Fabricatores ciborum etiam adhibent eam ut stratum protectivum, quod cibos diutius recentes servat, quia umorem retinet et putrefactionem leniter durantem in itinere et custodia tardat. Studia demonstraverunt HPMC substituere vetera emulsificans chimica rationem habere et ex perspectiva sanitatis et ex angulo pecuniae. Consummatores hodie scilicet vident cibos suos minus substantias chimicas continere, itaque hoc optime convenit cum praesentibus tendentibus mercati. Quod HPMC praecipue utile reddit est facilitate qua in varias recens ducitur formulas tamenque proprietates suas functionales retinet, adiuvando societates cibarias ad crescentes desideria pro alternativis naturalibus respondendum sine qualitate vel vita conservandi compromittenda.

Applicationes in Cura Corporis et Cosmetica

HPMC in Productis Cutaneis et Capillorum

Multi producta cutanea et capillorum continent Hydroxypropyl Methylcellulosam (HPMC), quod bene fungetur ut crassator, cedens cremis et lotionibus illam pulchram, lenem consistentiam, quam homines volunt. Praeterea HPMC non irritat cutinem, igitur bene convenit in producta ad personas cum cutibus sensibilibus, quod multae personae nunc quaerunt. Alium bonum? Retinet producta stabila diutius. Cosmetica non ita cito dissolvuntur, cum HPMC pars mixture sit, quod meliorem qualitatis custodiam significat a vaso ad usum. Pro mercaturis, hoc valde refert, quod emptores saepe adhaerent brandis, in quibus confidunt. Hac de causa fabricatores multi palam HPMC in listis ingredientorum et in materialibus mercandi ponunt, eamque inter principales componentes referunt, quae producta sua fiducia digna efficiunt.

Crassificans Non-Toxicus pro Solutionibus Cosmeticis Veganis

Nunc homines plures quaerunt cosmética vēgāna, et cupiunt tamen ut adiectīvae cutī non noceant et bene valeant. HPMC hic optime valet. Quod HPMC praestantissimum reddit, est sua versatilitas. In omnibus generibus productorum pulchrorum valet, sive in basi, sive in cremis, sive in curis cutis specialibus. Cum emptōrēs cautiōreś sint de contentis in ornatū, multi recedunt ā optionibus syntheticīs. Hic HPMC maxime elūcet ut praedicātiō. Fābricae quae HPMC in librīs mercātoriīs laudant, attentionem captant emptōrum cōnscentiae ambientalis deditōrum, qui de sustentābilitate et prōductiōne ēthica in industria bellōris curant.

HPMC in Picturis, Tegmentis, et Adhaesivis

Compositiones Picturae Aquae Basis cum HPMC

Hydroxypropylis Methylcellulosae, vulgo HPMC, munere suo fungitur in picturis aquae basis praecipue quod misturae crassitudinem vel viscositatem regulet. Uso suo recto, hoc efficit superficiem politam quam omnes optant cum parietes aut mobilia pinguntur. Quod HPMC praecipue pretiosam reddit est quomodo pigmenta aequaliter per picturam diffundit. Sine hac distributione aequali, colores maculosi vel inaequales videntur postquam siccantur. Pingendi fabricatores saepe in HPMC confidunt cum studiis indiquent quod haec composita diutius in mercatorum scaffis manent. Haec longior duratio significat minus praeda ante usum abiciuntur, quod totum remedium minuit. Praeterea, ementes proficiuntur quod minus saepe pingere rursus necesse est cum tecta qualitatem diutius conservent potius quam celeriter post applicationem dissolvantur.

Munus Adhaesionis Meliorandum in Applicationibus Industrialibus

HPMC munere principalis fungitur in adhesivis industrialibus dum vim et durabilitatem eorum augent. Cum ad misturas adhesivas additur, melius adhaerere superficiebus et vinculum ipsum in variis conditionibus retinere adiuvat. Unum magnum emolumentum ex eo oritur quod HPMC aquam retinet bene inter applicationes. Haec proprietas rem accelerat in fabricis quia materia citius solidatur nec qualitas amittitur. Tempus brevius factum in directis opificum expensis minuitur in variis industriae. Acta industria perbene constanter declarant producta HPMC continere fiabilius per longum tempus, quod explicat cur tantae copiae societatum hanc rem adhuc sequantur licet novae sententiae in mercatum intrant.

Sustentabilitas et Beneficia Environmental

Proprietates Biodegradabiles Hydroxypropyl Methylcellulosae

Hydroxypropylis Methylcellulosae, seu HPMC breviter, praecipue notabilis est quod in ambiente natura dissolvitur, id quod eam multo meliorem reddit quam multas alias chemicas antiquas. Cum manufactores HPMC in suis productis pro materialibus syntheticis incipiunt uti, pollutionem remittunt. Commoda non solum naturae sunt. Multae artes et commercia haec instituta iam susceperunt ut partem maioris curae de sustentatione. Custodes ambientis sicut EPA et Greenpeace monuerunt quomodo HPMC iuvet remittere inopiis cum teneat fabricas mundiores. Plures et plures mercatores nunc HPMC et similes biodegradabiles sectantur. Homines nunc curant unde res eorum veniant, itaque mercatores qui ad materia meliora convertunt clientelas trahunt qui vultunt operas ambientis probare. Praeterea, minus pendet a materia petrolei cum talia commutantur.

Minuendo Pedalitatem Carbonis Per Alternativas Vegetabiles

Ad transitionem ad HPMC ex plantis derivatum praebet industriis viam realem ad minuendos carbonis pedes, dum tamen adimplentur universalia delecta de sustentatione. Cum societates transitionem efficiunt e materialibus traditionalibus ad HPMC, eminet praecipue diminutio gasorum serra secundum investigationes in diariis environmentalibus editas. Haec transformatio iam non solum de rationibus ESG agit, sed necessaria fit ob desideria consumerum hodiernorum. Cernamus ad sectorem vestimentorum ciborum exempli gratia, ubi marcae HPMC magis magisque utuntur, quia emptores de optionibus amicis curant. Impetus ad HPMC in variis manufacturandi ramis includendum ostendit cur materiae istae praestent in reddenda productione viridi, sine qualitatis vel perficiendi normarum amissione.

Innovationes Industriales Nascentes

HPMC in Productione Ceramicorum et Typographia 3D

Hydroxypropyl Methylcellulose, quae vulgo HPMC dicitur, modum quemadmodum ceramica conficitur et imprimatur hodie mutat. Quid facit HPMC specialem? Haec materiae inter se copulari optime valet dum ceramica producitur, qua de causa producta ultima plerumque diutius durant et melius videntur. Pro manufacturis cupientibus ceramica sua contra condiciones asperas resistere, hoc valde refert. Quoad impressionem 3D, HPMC etiam magnam partem agit. Eius aditione in filamentis, operatio eorum melioratur, ita ut impressa usque adhuc expolitiora et fortiora fiant. Designatores et ingeniarii cum HPMC laborare amant quod eos iuvat formas intricatas accurate effingere et interea sumptus moderari. Investigatores iam novis modis HPMC in variis manufacturae rationibus utendis inquirunt, ab implantis medicinalibus ad structuras architectonicas, ita ut portae ad multas applicationes creativas in pluribus artibus aperiantur.

Applicationes Avanzatae in Tegmentis Specialibus

Hydroxypropyl-methylcellulose adit in tecturas speciales ubi omnes adiumenta in diversis generibus sectorum, ut sunt automotiva et electronica, afferre videtur. Experientiae demonstrant quod HPMC tecturis additum eas contra attritionem firmiores reddat dum durationem ante reponendum auguerit. Haec res maxime valet pro productis quae cotidie in condicionibus asperis utuntur, ut motus partes aut tabularia circuituum in telephonia. Fabricatores iam novis compositionibus cum HPMC experientur ad vetera problemata in technologia tecturarum solvenda. Exempli gratia, quaedam commercia hoc materia utuntur ad tecturas impervias aquae pro instrumentis externis creandas. Pretium maximum ex solutione problematum specificorum oritur quibus tecturae communis vix satisfaciunt, id quod tutelam meliorem pro machinis pretiosis et instrumentis sine compromissione qualitatis aut durationis praebet.

Sectio FAQ

Quid est Hydroxypropylis Methylcellulosa (HPMC) saepe adhibita in industria aedificandi?

HPMC saepe in industria aedificandi adhibetur ad meliorandum opera cementi, adhasives pro tesseris et compositiones mortarii per augmentum tractabilitatis, adhaesionis, retentionis aquae et praeventionem labefactationis.

Cur praeferatur HPMC in fabricatione medicamentorum?

HPMC in fabricatione medicamentorum praeferatur ad creandas capsulas vegetarianas quae emendant distributionem pharmacorum et bioaccessibilitatem, pariter desideria consumptorum pro productis sine notis obscuris et vegetalibus pascuntur.

Quomodo HPMC proficit industriae alimentariae?

In industria alimentaria, HPMC stabilizat compositiones panificii et lactarii et fungitur emulsificatore vegetabili, qua ex re qualitas productorum augetur et congruentia cum appetentibus naturalibus ingredientibus servatur.

Qualem partem HPMC gerit in cura personali et in cosmetica?

HPMC ut diluentis non noxi in cura personali et in cosmetica adhibetur, texturam, stabilitatem et aptitudinem pro cutibus delicatis praebens, et formulatis veganicis subvenit.

Quomodo HPMC ad sustentabilitatem confert?

HPMC praebet ad sustentabilitatem propter suas proprietates biodegradabiles et vim ut impensam ambientalem et pedes carbonis minuat, congruens cum conatibus globalibus ad praxim viridorem.

Index Rerum

- Applicationes Industriae Constructionis HPMC

- HPMC in Fabricatione Medicamentorum

- Usus Hydroxypropyl Methylcellulosae in industria cibaria

- Applicationes in Cura Corporis et Cosmetica

- HPMC in Picturis, Tegmentis, et Adhaesivis

- Sustentabilitas et Beneficia Environmental

- Innovationes Industriales Nascentes

- Sectio FAQ

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ