Deall Effaith Chwyldrolog Celfen Gellwlos Rhaglen Cerameg yn Ymgyrchu Twristiaeth Fodern

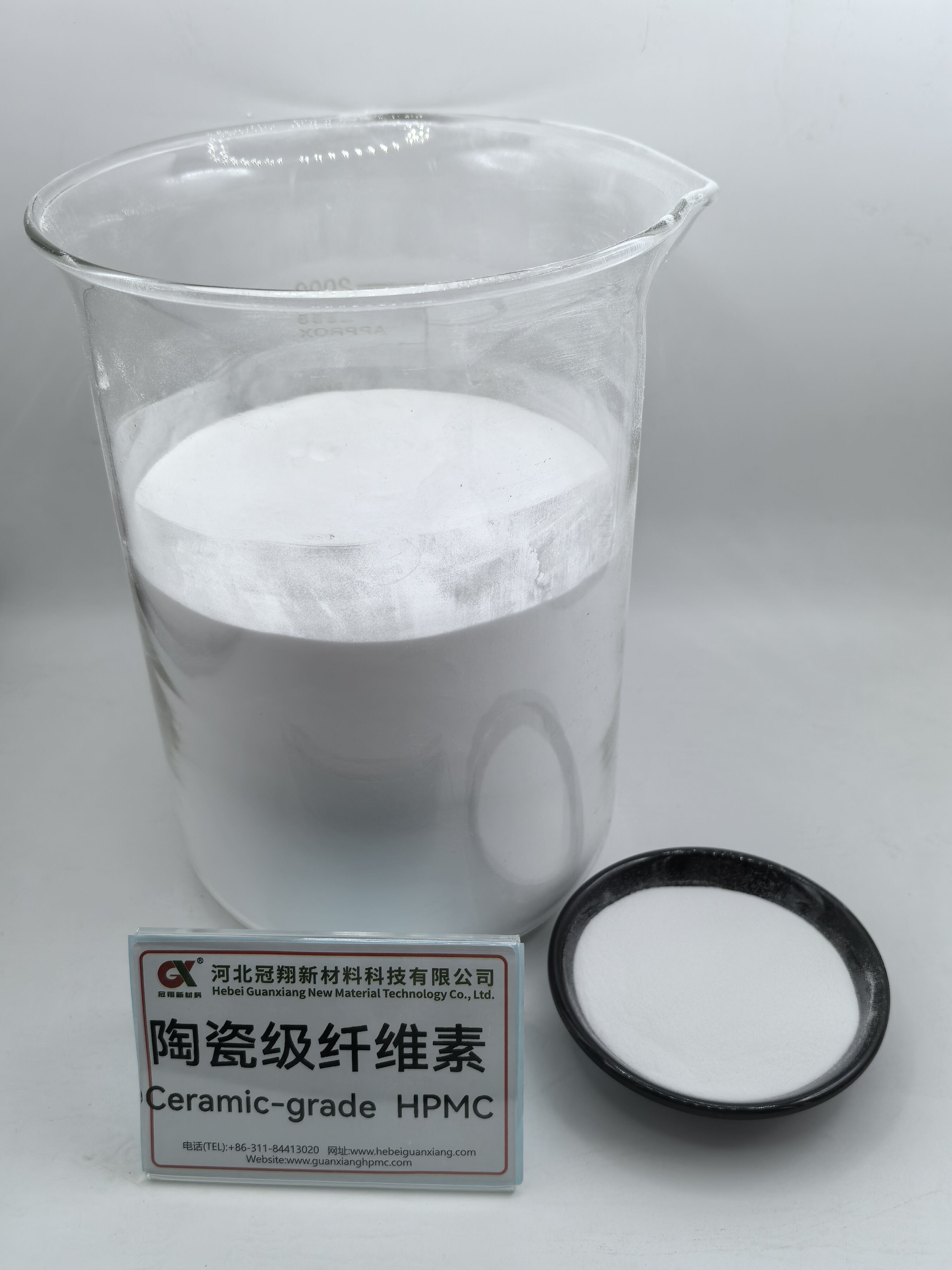

Yn y tirwedd gynhyrchu diweddar heddiw, gelluloesi ar draws cêrámig wedi dod i'r amlwg fel materol sy'n newid y gêm sydd yn trawsnewid sawl diwydiant. Mae'r ffyrdd arbennig o gelwlylos, a gafodd ei ddynnu o ffynonellau planhigion cynaliadwy, yn cynnig priodweddau eithriadol sy'n ei wneud yn werthfawr i gynhyrchu ceramig a amryw o applicationau diwydiant. Wrth i gynhyrchwyr chwilio'n gynyddol am ddeunyddiau cyfeilliondrefn ac uwch-berfformiad, mae celwlylos gradd ceramig yn sefyll allan am ei amrywiolrwydd a'i effeithiolrwydd.

Mae taith selwlylos gradd ceramig o boblogaer naturiol i bŵer tebyg iard yn cynrychioli un o'r datblygiadau mwyaf yw drutweithiau gwyddoniaeth deunydd. Mae ei strwythur moleciwlaidd unigryw a'i alluoedd prosesu wedi agor posibiliadau newydd mewn manwerthu ceramig, gan arwain at wella ansawdd y cynnyrch ac is-gymhwyso ar yr amgylchedd.

Priodweddau a Nodweddion Craidd

Cyfansoddiadau a Strwythur Gymhleth

Mae selwlylos gradd ceramig yn cyfansoddi o feiriau selwlylos uchelgeintiedig sydd wedi'u prosesu'n benodol ar gyfer rhaglenni ceramig. Mae gan y deunydd strwythur crysialaidd unigryw sy'n darparu priodweddau clymu eithriadol a rheolaeth rheidoleg. Mae ei drefn foleciwlaidd yn galluogi amldosiad uwch mewn lluris ceramig tra'n cadw hydtrydedd cyson trwy'r broses wersnu.

Mae lefelau purdeb yn y gradd gerdameg o gellwlos yn eithriadol uchel, fel arfer yn rhagor na 99.5%. Mae'r purdeb eithriadol hwn yn sicrhau llaiafswm o ryngweithio â ffurfiadau ceramig ac yn helpu i gyrraedd canlyniadau optimol mewn cynhyrchion terfynol. Mae'r dosbarthiad hyd craffter sydd wedi'i reoli'n ofalus yn cyfrannu at ei berfformiad eithriadol mewn amrywiaeth o applicationau.

Priodweddau Ffisegol a Nodweddion Perfformiad

Un o'r agweddau mwyaf hanfodol gradd gerdameg o gellwlos yw ei alluoedd cadw cyflwr strwythurol o dan amodau eithafol. Mae gan y materol sefydlogrwydd thermol da, sydd yn hanfodol ar gyfer prosesu ceramig wrth dymhereddau uchel. Mae ei fformiofa craffter unigryw yn darparu cryfder gwell a chysoniant i gynhyrchion ceramig tra'n lleihau diffystion ac yn gwella ansawdd cyffredinol.

Mae ardal arwyneb uchel y deunydd a dimensiynau ffibr benodol yn cyfrannu at ei alluoedd gwarthu gwell. Mae'r nodweddion hyn yn galluogi dosbarthiad gwell o gronynnau mewn cymysgedi ceramig ac yn helpu cyrraedd priodweddau rheolaidd optimaidd yn ystod prosesu.

Buddion Manwerthu a Gwelliannau Broses

Effeithlonrwydd Cynhyrchu Gwella

Pan fo'n cael ei chynnwys yn brosesau manwerthu ceramig, mae selliwlos gradd ceramig yn gwella effeithlonrwydd cynhyrchu yn ystyrlad. Mae'n galluogi rheoli gwell dros hydferddwch y llif ac yn helpu cadw nhrefniant cyson drwy gydol y bechneg waith. Mae hyn yn arwain at leihau amseroedd cynhyrchu a gwella cyfraddau allbwn, gan arwain at gynhesiadau sylweddol ar gost.

Mae diffusnadwyedd eithriadol y deunydd a'i sefydlogrwydd mewn systemau dŵr yn helpu atal materion o settlo a gwahanu sydd yn gyffredin mewn prosesu ceramig. Mae hyn yn trosglwyddo i lai o ryngau cynhyrchu a chwynion cynhyrchion mwy cyson.

Rheoli Ansawdd a Chysondeb y Cynnyrch

Mae defnyddio cellwlos gradd ceramig yn arwain at reolaeth ansawdd gwell mewn cynhyrchu ceramig. Mae ei nodweddion perfformiad cyson yn helpu cyrraedd dosbarthiad unffurff o gronynau ac yn atal aglomeriad, gan gynhyrchu cynhyrchion terfynol â chyflwr strwythurol gwella a llai o ddiffeniadau.

Mae gall y deunydd gael ei wahanu i ffynhonnell blanhigion adnewyddadwy ac yn gall cael ei brosesu gan ddefnyddio dulliau sydd â chymhwyster am yr amgylchedd. Mae ei gynhyrchu'n creu waste isafswm ac yn gofyn am lai o ynni o gymharu â amgenion synthetig.

Buddion Amgylcheddol a Chynaliadwy

Proses Cynhyrchu Cyffredinol i'r Amgylchedd

Wrth i gynaliadwydd dod yn fwy ac yn fwy bwysig mewn manwerthu, mae cellwlos gradd ceramig yn cynnig buddion amgylcheddol sylweddol. Mae'r deunydd yn deillio o ffynhonnell blanhigion adnewyddadwy ac yn gall cael ei brosesu gan ddefnyddio dulliau sydd â chymhwyster am yr amgylchedd. Mae ei gynhyrchu'n creu waste isafswm ac yn gofyn am lai o ynni o gymharu â amgenion synthetig.

Mae natur bywyd-adnabodol selwlylos gradd ceramig yn golygu bod unrhyw gynhyrchion danlan yn cael effaith fach iawn ar yr amgylchedd. Mae hyn yn cyd-fynd â chynaliadau tyfiant y diwydiant tuag at arferion cynhyrchu cynaliadwy ac allyriadau carbon llai.

Effaith Amgylcheddol Leihau

Mae defnyddio selwlylos gradd ceramig yn helpu lleihau effaith amgylcheddol gweithgynhyrchu ceramig mewn sawl ffordd. Mae'n galluogi tymhereddau ffwrno iselach mewn rhai aplicaethau, sy'n arwain at leihau defnydd o ynni. Mae nodweddion prosesu effeithiol y deunydd hefyd yn arwain at lai o sbwriel yn ystod y gweithgynhyrchu.

Ychwanegol at hynny, mae natur adnewyddadwy ffynonellau selwlylos yn helpu i gadw adnoddau nad ydynt yn adnewyddadwy a ddefnyddir fel arfer mewn prosesu ceramig. Mae'r gyfraniad hwn i arferion cynhyrchu cynaliadwy yn gwneud selwlylos gradd ceramig yn opsiwn sydd yn dod yn fwy drawiadol i gynhyrchwyr sydd â gof am yr amgylchedd.

Cymwysiadau a Defnyddiau Diwydiant

Gweithgynhyrchu Ceramig Traddodiadol

Yn y broses gynhyrchu ceramig traddodiadol, mae sellwlos gradd ceramig yn gweithio fel clyfr a chymorth prosesu hanfodol. Mae'n gwella cryfder corff ceramig heb eu ffwrno, yn galluogi cadw siâp well yn ystod y broses, ac yn cyfrannu at welliant ar y gorwel ar gyfer cynhyrchion terfynol. Mae perfformiad cyson y deunydd yn ei wneud yn enwedig werthfawr wrth gynhyrchu siapiau a chydrannau ceramig cymhleth.

Mae priodweddau clymu rhagorol y deunydd yn helpu i leihau diffygion mewn cynhyrchion ceramig tra'n gwella integreiddio strwythurol cyffredinol. Mae hyn yn arwain at gynhyrchion terfynol o ansawdd uwch ac i gyfraddau gwarthnod â chynhesiadau isel mewn manwerthu.

Cymwysiadau Ceramig Uwch

Mewn rhaglenni ceramig uwch, mae selwlylos gradd ceramig yn chwarae rôl hanfodol mewn datblygu cynhyrchion o uchel berfformiad. Mae ei ddefnydd mewn ceramegau technegol yn helpu i gyrraedd manylebau union ac eiddo mechanig gwell. Mae cydbwyso'r deunydd â amrywiaeth o ffurfiau ceramig yn ei wneud yn werthfawr mewn datblygu cynhyrchion ceramig newydd ar gyfer rhaglenni arbenigol.

Mae perfformiad cyson a phriodoleddau dibynadwy selwlylos gradd ceramig yn ei wneud yn enwedig addas ar gyfer rhaglenni ceramig uwch ble mae manyleb a chyfrifoldeb yn bendant. Mae ei ddefnydd yn parhau i ehangu wrth i raglenni newydd gael eu datblygu mewn amryw o sectorau diwydol.

Trendiadau a Datblygiadau yn y Dyfodol

Newid a Chwilio

Mae ymchwil barhaus yn dal i ddarganfod rhaglenni posibl newydd ar gyfer selwlylos gradd ceramig. Mae gwyddonwyr a chynhyrchwyr yn archwilio fersiynau wedi'u haddasu o'r deunydd gyda phriodoleddau gwella ar gyfer rhaglenni penodol. Mae'r datblygiadau hyn yn addo ymhelaethu pellach ar ddefnyddio selwlylos gradd ceramig mewn amryw o diwydiannau.

Mae'r ffwcs ar ddatblygu deunyddiau cynaliadwy wedi arwain at gynyddu diddordeb yn y gweithgynhyrchu a'r rhagosodiadau o gellosglws gradd ceramig. Mae technegau prosesu newydd a modiwlâu yn cael eu hymchwilio i wella'i nodweddion perfformiad yn bellach.

Tyfu’r Farchnad a Mabwysiadu'r Diwydiant

Mae’r farchnad ar gyfer cellosglws gradd ceramig yn parhau i tyfu wrth i fwy o gynhyrchwyr gydnabod ei fuddiannau. Mae’r galw am bobl merch cyrstal o ansawdd uchel a brosesau gynhyrchu cynaliadwy’n gyrru’r mabwysiad trwy amryw o ddibyniau. Disgwylir i’r tyfiant hwn barhau wrth ddarganfod rhagosodiadau a buddiannau newydd.

Mae mabwysiadu’r diwydiant yn enwedig cryf yn rannau sydd â rheoliadau amgylcheddol llym a chrynydd tyfu ar arferion cynaliadwy. Mae perfformiad y deunydd a’i fuddiannau amgylcheddol wedi’u profi, ac felly maen nhw’n ddewis atractiwr i gynhyrchwyr sydd eisiau gwella eu brosesau tra’n lleihau eu effaith amgylcheddol.

Cwestiynau Cyffredin

Sut mae seliwlos gradd ceramig yn gwella ansawdd cynnyrch ceramig?

Mae seliwlos gradd ceramig yn gwella ansawdd y cynnyrch trwy ddarparu dosbarthiad gwell o olion, cryfhau clymu, a phriodweddau reolaidd fwy cyson yn ystod prosesu. Mae hyn yn arwain at lai o ddiffygion, integreiddio strwythurol gwell, a chynhyrchion terfynol mwy cyson.

Pam mae seliwlos gradd ceramig yn ddwyreiniol i'r amgylchedd?

Mae’r deunydd yn dod o ffynonellau planhigion adnewyddadwy, mae angen llai o ynni i’w brosesu na dimsynnau cymysg, ac mae’n dadfeithgar. Gall ei ddefnyddio leihau defnyddio ynni yn y manwerthu ceramig ac yn creu llai iawn o sbwriel amgylcheddol.

A all seliwlos gradd ceramig gael ei ddefnyddio mewn pob math o application ceramig?

Er bod cellwlos gradd ceramig yn ddigon versatâl, dibynnodd ei addasrwydd ar ofynion penodol y cais. Mae'n perfformio'n eithriadol o dda mewn mwyafrif y ceiramig traddodiadol a chyfoes, ond dylid ei asesu am gydnawsedd â chyflwr penodol y brosesu a gofynion defnydd diwethaf.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ