Modern Requirements for Fast and Dependable Tile Work

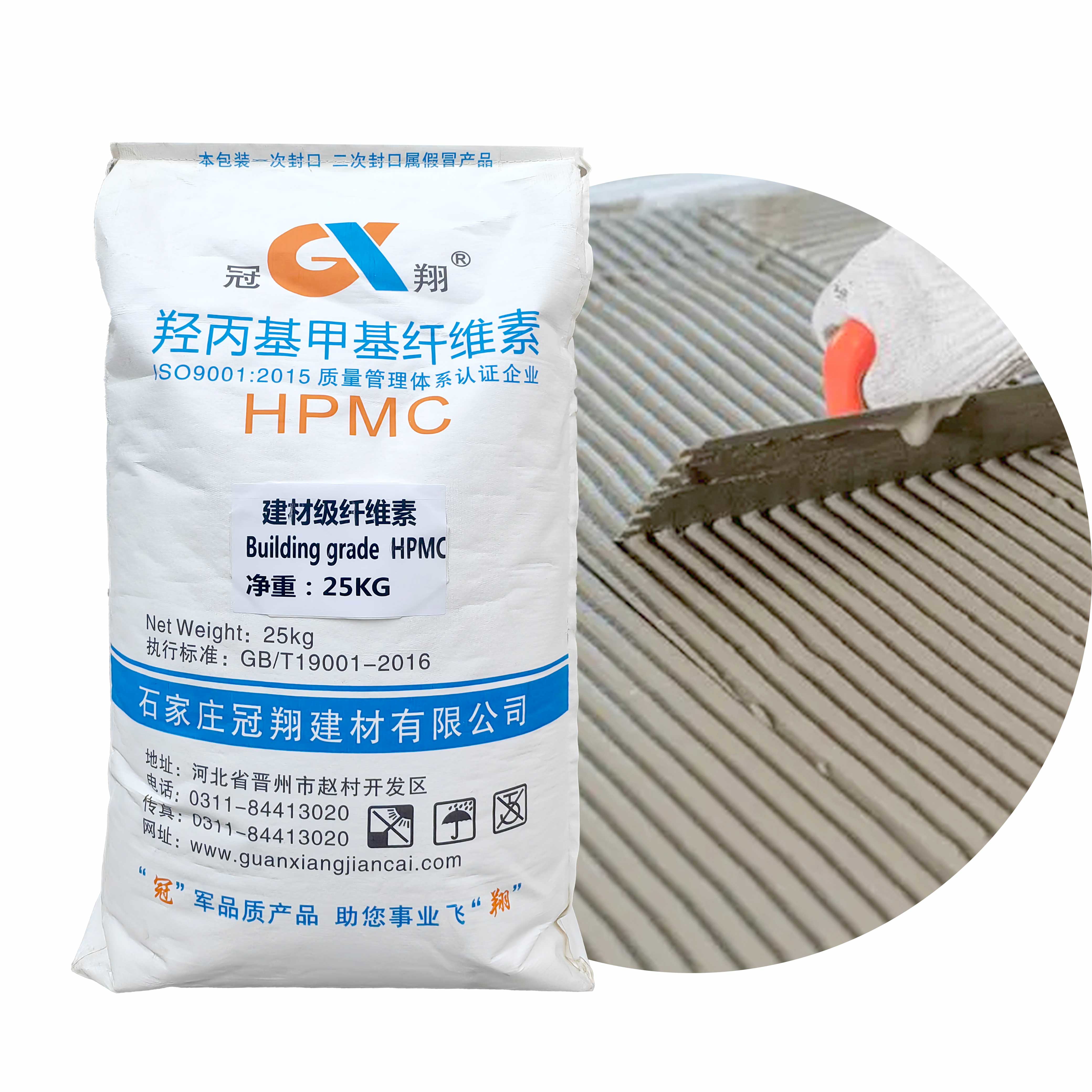

In today’s construction environment, installers and project managers face tight schedules, higher aesthetic expectations, and stricter durability requirements. HPMC Tile Adhesive has become a go-to solution because it delivers fast-setting performance without sacrificing long-term bond strength. This adhesive formulation, containing Hydroxypropyl Methylcellulose, is engineered to provide improved workability, consistent mixing, and reliable water retention. Those properties combine to make HPMC Tile Adhesive particularly well suited to projects that require both speed and dependability — from residential remodels to large commercial installations. By reducing rework, minimizing waste, and helping crews work more efficiently, HPMC Tile Adhesive contributes directly to faster project turnover and better long-term outcomes.

Performance Fundamentals of HPMC Tile Adhesive

Mechanism of Improved Adhesion and Hydration

HPMC Tile Adhesive enhances the hydration process of cementitious components by retaining moisture in the adhesive bed. This controlled water retention promotes complete hydration of cement particles, which leads to denser microstructures and stronger bonding interfaces. The action of Hydroxypropyl Methylcellulose in the mix reduces rapid water loss, allowing adhesives to cure evenly and form consistent contact with both tile faces and substrates. The result is that HPMC Tile Adhesive helps prevent partial cures and hollow spots that commonly lead to debonding or tile failure.

Role in Reducing Shrinkage and Internal Stress

When water evaporates unevenly from a tile bed, internal stresses and shrinkage cracks can form, undermining the bond. HPMC Tile Adhesive moderates the drying profile by extending the workable time and controlling water release. Because the adhesive cures more uniformly, it reduces micro-cracking and minimizes shrinkage-related stresses. For installation teams, this means a lower risk of post-installation failures and fewer callbacks. Over time, the adhesive layer created by HPMC Tile Adhesive remains more cohesive and better able to support both heavy loads and thermal movement.

Time-Saving Advantages with HPMC Tile Adhesive

Faster Application and Reduced Labor Time

One of the practical benefits of HPMC Tile Adhesive is improved spreadability and trowelability. Installers can apply the adhesive more smoothly and at a consistent thickness, minimizing the need for repeated raking or patching. The extended open time provided by the HPMC component means that tiles can be set and adjusted without an undue rush, yet the adhesive still reaches a dependable initial set within project-appropriate timeframes. This combination — easy application plus timely setting — shortens overall labor hours and helps contractors meet tight deadlines.

Simplified Large-Area and Large-Format Tile Work

Large-format tiles and continuous floor areas are notorious for slowing down installation due to the need for careful alignment and full coverage. HPMC Tile Adhesive supports larger coverage areas with consistent performance, reducing the need to work in excessively small sections. When combined with appropriate trowel selection and good substrate preparation, HPMC Tile Adhesive enables teams to cover bigger areas per crew-hour, accelerating project schedules without compromising quality.

Workability and Installer Advantages

Better Control During Tile Adjustment

Installers benefit from the forgiving nature of HPMC Tile Adhesive while positioning tiles. The product’s controlled slip resistance and enhanced plasticity reduce tile movement after placement and support fine adjustments. Whether aligning delicate mosaic tiles or setting heavy stone slabs, crews find that HPMC Tile Adhesive offers a balance of tack and slippage that streamlines the layout process. That user-friendly behavior reduces the incidence of misalignment and the rework that can derail timelines.

Compatibility with Various Tools and Techniques

HPMC Tile Adhesive adapts well to both manual application and mechanized tiling systems. For projects employing automated dispensing or robotic laying equipment, the consistent rheology of the adhesive helps maintain steady flow and precise deposition. For traditional hand-applied jobs, the improved troweling characteristics make it easier to achieve uniform beds. In all cases, the product’s stability during the working period reduces application mistakes and enhances crew productivity.

Durability and Longevity Provided by HPMC Tile Adhesive

Resistance to Environmental Challenges

Once set, tile systems must endure moisture cycles, temperature variations, and mechanical loads. The cured matrix produced by HPMC Tile Adhesive exhibits improved resistance to moisture penetration and thermal cycling, reducing the likelihood of freeze-thaw damage or adhesive breakdown in exterior applications. In interior wet areas like bathrooms and kitchens, the adhesive helps maintain a robust bond that resists the weakening effects of continuous humidity exposure.

Ability to Accommodate Substrate Movement

Buildings expand, contract, settle, and vibrate. The bonded layer must absorb these small movements without transferring stress to the tile surfaces. HPMC Tile Adhesive provides a certain degree of elasticity and stress absorption that reduces crack propagation and tile displacement. This resilience is especially valuable in mixed-material assemblies where substrates and tile materials have differing thermal coefficients or flexural properties.

Application-Specific Benefits

Advantages for Large-Format Porcelain and Natural Stone

Large-format porcelain and natural stone panels demand adhesives that can fill voids, maintain contact, and hold high weights without sagging. HPMC Tile Adhesive supports these needs by producing a stable bed that resists slumping on walls and maintains full-bed contact on floors. The controlled rheology and improved yield create reliable coverage under heavy tiles, which helps prevent hollow areas and ensures long-term performance.

Suitability for Rapid-Renovation and Turnkey Projects

In renovation and commercial fit-out contexts, turnaround time is critical. HPMC Tile Adhesive’s combination of workable placement, reliable initial set, and durable final bond makes it an excellent choice for turnkey projects that must meet strict handover dates. Quick return-to-service for floors and wet areas minimizes business disruption and reduces the risk of schedule overrun.

Technical and Quality Considerations

Consistency in Manufacturing and On-Site Performance

Reliable performance begins with consistent production. Quality-controlled manufacturing processes ensure that HPMC Tile Adhesive batches have predictable viscosity, setting profiles, and bonding characteristics. This reproducibility makes planning easier for procurement and installation managers — when the product specification calls for HPMC Tile Adhesive, on-site teams can expect uniform behavior from bag to bag.

Testing and Standards Compliance

Top-quality HPMC Tile Adhesive formulations are tested to meet or exceed relevant industry standards for bond strength, slip resistance, open time, and water retention. Where applicable, technical data sheets provide guidance on appropriate substrate preparation, trowel sizes, and cure times. Adhering to these guidelines maximizes the likelihood of achieving long-term success with HPMC Tile Adhesive.

Sustainability and Lifecycle Value

Reduced Waste and Better Material Efficiency

By improving spreadability and reducing the need for rework, HPMC Tile Adhesive lowers material consumption and waste. Fewer failed installations mean fewer removed tiles and less discarded adhesive. Over the life of a building, better initial installations translate to fewer repairs, reducing embodied carbon and lifecycle costs. Contractors and owners both benefit from the increased efficiency that HPMC Tile Adhesive provides.

Alignment with Green Building Practices

Many modern HPMC Tile Adhesive formulations are designed with environmental considerations in mind, including lower volatile organic compound levels and more efficient production methods. For projects pursuing green certifications, selecting adhesives with documented environmental profiles can contribute positively to sustainability goals while still delivering the robust performance expected from HPMC Tile Adhesive.

Practical Tips for Successful Use of HPMC Tile Adhesive

Proper Substrate Preparation Practices

Even the best adhesive cannot compensate for a poorly prepared substrate. For optimum results with HPMC Tile Adhesive, ensure that surfaces are clean, sound, flat, and free of dust, oils, or laitance. Repair cracks and level uneven areas before applying adhesive. When guidelines call for primers or bonding agents, follow them — proper substrate prep enhances the effectiveness of HPMC Tile Adhesive and reduces potential failure modes.

Choosing the Right Trowel and Application Method

Trowel selection matters: the right notch size ensures adequate adhesive coverage for the tile size and backing. HPMC Tile Adhesive performs well across a variety of trowel profiles, but installers should choose a notch that produces full contact beneath the tile. For large or heavy tiles consider back-buttering in addition to full-bed application to achieve complete coverage and prevent hollow spots. Consistent application technique magnifies the benefits that HPMC Tile Adhesive brings to a project.

Common Pitfalls and How HPMC Tile Adhesive Mitigates Them

Avoiding Hollow Spots and Air Pockets

Hollow spots are a leading cause of tile failure. Because HPMC Tile Adhesive has good workability and water retention, it helps installers achieve complete bed contact. Encouraging full adhesive coverage with the correct trowel and application method prevents cavities and improves the longevity of the tiled system.

Managing Open Time and Setting Profiles on Hot or Dry Days

Hot weather can shorten the open time of adhesives, causing premature skinning and poor bonding. HPMC Tile Adhesive’s water-retention characteristics stabilize the open time even under warm and dry conditions, giving installers the leeway to adjust tiles without compromising cure or adhesion. This temperature resilience reduces season-related variability in install quality.

Advanced Uses and Industry Trends

Integration with Heated Floor Systems and Specialty Substrates

As more buildings use radiant heat or specialty substrates, adhesives must perform under varied thermal loads and bonding challenges. HPMC Tile Adhesive has proven suitable for many such applications when selected according to manufacturer specifications. Its ability to maintain bond integrity under thermal cycling makes it a good match for modern systems that combine comfort and design performance.

Role in Prefabrication and Offsite Construction

Offsite construction and prefabrication demand adhesives compatible with controlled manufacturing workflows. HPMC Tile Adhesive’s predictable setting behavior and consistent rheology make it useful in prefabrication environments where tiles or panels are assembled in factory conditions and later installed on-site. That compatibility enables higher-quality finishes with less on-site labor.

FAQ

Benefits and primary advantages of using HPMC Tile Adhesive

HPMC Tile Adhesive provides improved workability, consistent water retention, stronger final bond strength, and reduced shrinkage. These advantages translate into fewer installation errors, less waste, and longer-lasting tile systems.

Best practices for applying HPMC Tile Adhesive in large-format tile work

Use the recommended trowel size, consider back-buttering for heavy or large tiles, ensure full adhesive contact, and follow substrate preparation guidelines. These practices help maximize the unique benefits of HPMC Tile Adhesive.

Suitability of HPMC Tile Adhesive for wet and exterior locations

When the correct product formulation is chosen and installation guidelines are followed, HPMC Tile Adhesive delivers excellent moisture resistance and thermal stability, making it appropriate for bathrooms, poolsides, and many exterior applications.

How HPMC Tile Adhesive contributes to cost savings over a building lifecycle

Although initial material cost may be modestly higher than some basic mortars, the long-term savings from reduced rework, longer service life, and lower maintenance needs produce a favorable lifecycle cost advantage when using HPMC Tile Adhesive.

Table of Contents

- Modern Requirements for Fast and Dependable Tile Work

- Performance Fundamentals of HPMC Tile Adhesive

- Time-Saving Advantages with HPMC Tile Adhesive

- Workability and Installer Advantages

- Durability and Longevity Provided by HPMC Tile Adhesive

- Application-Specific Benefits

- Technical and Quality Considerations

- Sustainability and Lifecycle Value

- Practical Tips for Successful Use of HPMC Tile Adhesive

- Common Pitfalls and How HPMC Tile Adhesive Mitigates Them

- Advanced Uses and Industry Trends

- FAQ

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ