Construction Industry Applications of HPMC

Enhancing Cement-Based Materials With Hydroxypropyl Methylcellulose

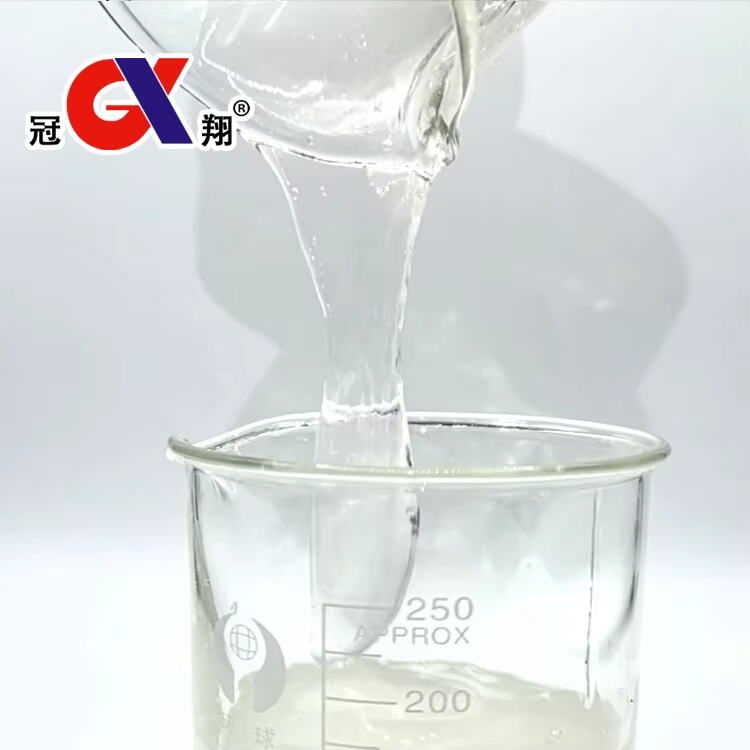

Getting to grips with how Hydroxypropyl Methylcellulose or HPMC affects cement based materials makes all the difference when it comes to improving building methods. What we find is that HPMC really does make these materials easier to work with and stick better together, giving us much better finishes on walls and surfaces. Studies show that when mixed into mortar, HPMC holds onto water longer than usual. This matters because cement needs time to properly hydrate before setting. The result? Stronger structures that last longer without cracking or flaking off. There's another benefit too. HPMC acts like a sort of shield around particles in the mix, keeping them suspended uniformly throughout. This even distribution is what keeps cement mixes from separating out during application, something contractors hate dealing with.

HPMC in Tile Adhesives and Mortar Formulations

Hydroxypropyl Methylcellulose, or HPMC as it's commonly known, makes a big difference in tile adhesives and mortar mixes. When mixed into these products, HPMC really helps strengthen how well tiles stick to whatever surface they're being applied to, which means buildings last longer without problems. A major plus of HPMC is that it holds onto water much better than other additives. This gives workers plenty of time to work with the adhesive before it starts setting up, something that can make all the difference on large jobs. Plus, when HPMC is part of the formula, there's far less chance of tiles sliding around after placement. This matters a lot when working on walls since tiles tend to slip down otherwise, causing frustration and wasted materials.

HPMC in Pharmaceutical Manufacturing

Hydroxypropyl Methylcellulose Capsules for Drug Delivery

Hydroxypropyl Methylcellulose, or HPMC for short, has become really important in making vegetarian capsules for delivering medications. Derived from cellulose, this stuff works great as a replacement for regular gelatin capsules, which many people avoid because they contain animal products. Research shows that when drugs come in HPMC capsules, they actually get absorbed better in the body, which makes these capsules perfect for slow release medicines. The reason? Well, HPMC forms a gel when it comes into contact with moisture, and this property helps regulate how fast the medicine gets released into the system. Plus, manufacturers can make these capsules completely without any animal ingredients at all, something that matches what more consumers are asking for nowadays. By adopting this technology, companies in the pharmaceutical field can reach out to folks who prefer plant-based alternatives whether for religious beliefs, health concerns, or just personal choice.

Vegetarian Capsules and Clean-Label Formulations

What makes Hydroxypropyl Methylcellulose (HPMC) so interesting for the pharmaceutical industry is how it helps create products with cleaner labels. People want to know exactly what goes into their medications these days, and there's been a huge shift toward natural ingredients across all sectors. Vegetarian capsules made from HPMC address this need directly since they don't contain any synthetic additives or animal-derived materials. Market analysts have noticed that companies switching to HPMC-based formulations tend to stand out in crowded markets because consumers appreciate straightforward labeling. With allergies and dietary restrictions becoming more common than ever before, HPMC plays a critical role in making sure people can still get necessary medications regardless of their dietary choices. The growing popularity of plant-based lifestyles means manufacturers who incorporate HPMC into their processes are better positioned to satisfy this expanding segment of healthcare consumers.

Food Industry Uses of Hydroxypropyl Methylcellulose

HPMC as a Stabilizer in Bakery and Dairy Products

The food industry is seeing more interest in Hydroxypropyl Methylcellulose or HPMC thanks to what it can do for product stability, especially when it comes to baked goods and dairy items. When added to bakery mixes, this stuff helps lock in moisture so products stay fresh longer on store shelves. Bakers love this because it means their loaves, cakes, and pastries don't dry out as quickly even without all those chemical preservatives. Another cool thing about HPMC is how it replaces fats in things like yogurt and milk alternatives while still keeping that rich, creamy feel people expect. This lets manufacturers create lighter versions of their products without making them taste watery or boring, which matters a lot in today's market where folks want healthier options but still crave good flavor. Industry research shows time and again that foods containing HPMC just plain taste better to most consumers, giving that satisfying mouthfeel everyone looks for. All these advantages are why we're seeing more companies turn to HPMC as they try to make their offerings both tastier and healthier at the same time.

Plant-Based Food Coatings and Emulsifiers

HPMC stands out as a plant based emulsifier and coating material that works wonders in food production. When added to things like sauces or salad dressings, it gives those products that rich, smooth mouth feel people love without any artificial feel. Food manufacturers apply it as a protective layer too, which keeps produce fresh longer by locking in moisture and slowing down spoilage during shipping and storage periods. Studies have shown that replacing traditional chemical emulsifiers with HPMC makes sense both from a health standpoint and cost perspective. Consumers these days want their food to contain fewer chemicals anyway, so this fits right into current market trends. What makes HPMC particularly useful is how easily it integrates into different recipes while still maintaining its functional properties, helping food companies meet growing demands for natural alternatives without compromising quality or shelf life.

Personal Care and Cosmetic Applications

HPMC in Skincare and Haircare Products

Many skincare and haircare products contain Hydroxypropyl Methylcellulose (HPMC) because it works great as a thickener, giving creams and lotions that nice, smooth consistency people want. What's good about HPMC is that it doesn't irritate skin, so it fits well in products for folks with sensitive skin types something lots of consumers are looking for these days. Another benefit? It keeps products stable longer. Cosmetics just don't break down as quickly when HPMC is part of the mix, and that means better quality control from bottle to application. For companies, this matters a lot since customers tend to stick with brands they can count on. That's why so many manufacturers prominently feature HPMC in their ingredient lists and marketing materials, positioning it as one of those key components that make their products trustworthy.

Non-Toxic Thickening for Vegan Cosmetic Solutions

More people are looking for vegan cosmetics these days, and they want thickening agents that don't harm their skin while still working well. HPMC fits the bill perfectly here. What makes HPMC so great is how adaptable it is. It works wonders in all sorts of beauty products, whether its foundation, lotions or even specialized skin treatments. As shoppers become pickier about what goes into their makeup, many are turning away from synthetic options. That's where HPMC really shines as a selling feature. Brands that highlight HPMC in their marketing materials tend to catch the attention of eco-conscious buyers who care deeply about sustainability and ethical production practices in the beauty industry.

HPMC in Paints, Coatings, and Adhesives

Water-Based Paint Formulations With HPMC

Hydroxypropyl Methylcellulose, commonly known as HPMC, serves an important function in water based paints mainly because it controls the thickness or viscosity of the mixture. When applied properly, this helps achieve that smooth finish everyone wants when painting walls or furniture. What makes HPMC really valuable is how it spreads pigments evenly throughout the paint. Without this even distribution, colors can look patchy or uneven once dry. Paint manufacturers often rely on HPMC since research indicates these formulations last longer on store shelves too. The extended shelf life means fewer batches get thrown away before they're used, which cuts down on waste overall. Plus, consumers benefit from needing to repaint less frequently as their coatings maintain quality over time rather than breaking down quickly after application.

Improving Adhesive Strength in Industrial Applications

HPMC plays a key role in industrial adhesives by boosting their overall strength and durability. When added to adhesive mixtures, it helps them stick better to surfaces and maintain that bond under various conditions. One major benefit comes from how well HPMC holds onto water during application processes. This characteristic actually speeds things up on factory floors because materials set faster without compromising quality. The savings in time translate directly into lower production costs for manufacturers across multiple industries. Industry reports consistently show that products containing HPMC perform reliably over long periods, which explains why so many companies continue to rely on this material despite newer alternatives entering the market.

Sustainability and Environmental Benefits

Biodegradable Properties of Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose, or HPMC for short, stands out because it breaks down naturally in the environment, which makes it much friendlier than many traditional chemical alternatives. When manufacturers start using HPMC in their products instead of synthetic materials, they actually cut down on pollution pretty substantially. The benefits go beyond just being kinder to Mother Earth too. Many different industries have begun adopting these practices as part of broader sustainability efforts. Environmental watchdog groups like EPA and Greenpeace have pointed out how HPMC helps cut back on waste accumulation while making factories run cleaner overall. We're seeing more and more businesses jump on board with biodegradable options like HPMC these days. People care about where their stuff comes from now, so companies that switch to greener materials tend to attract customers who want to support environmentally responsible operations. Plus, there's less dependence on oil-based raw materials when we make this sort of switch.

Reducing Carbon Footprint Through Plant-Based Alternatives

Switching to plant-based HPMC offers industries a real way to shrink their carbon footprints while still meeting worldwide sustainability goals. When companies make the switch from traditional materials to HPMC, they actually see significant drops in greenhouse gases according to research published in environmental journals. For many businesses, this isn't merely about ticking boxes on ESG reports anymore it's becoming essential due to what consumers want these days. Look at the food packaging sector for instance, where brands are increasingly turning to HPMC because shoppers care about eco-friendly options. The push to include HPMC across different manufacturing sectors shows why this material stands out when it comes to making production greener without sacrificing quality or performance standards.

Emerging Industrial Innovations

HPMC in Ceramic Production and 3D Printing

Hydroxypropyl Methylcellulose, commonly known as HPMC, is changing how ceramics get made and printed these days. What makes HPMC special? Well, it binds materials together really well during ceramic production, which means the final products tend to last longer and look better overall. For manufacturers wanting their ceramics to hold up under tough conditions, this matters a lot. When it comes to 3D printing, HPMC plays a big part too. Adding it to filaments improves how they work, so prints come out smoother and stronger than before. Designers and engineers love working with HPMC because it lets them make complicated shapes accurately while still keeping costs down. Researchers are already looking at new ways to use HPMC in different manufacturing settings, from medical implants to architectural components, opening doors for all sorts of creative applications across multiple industries.

Advanced Applications in Specialty Coatings

Hydroxypropyl Methylcellulose finds its way into specialty coatings where it brings all sorts of advantages to different sectors like cars and electronics. Studies show that when added to coatings, HPMC makes them tougher against wear and tear while extending how long they last before needing replacement. This matters a lot for products that face rough conditions daily, think engine components or circuit boards inside smartphones. Manufacturers are now experimenting with fresh formulas containing HPMC to solve old problems in coating technology. For instance, some companies have created waterproof coatings for outdoor equipment using this material. The real value comes from solving specific issues that standard coatings struggle with, which means better protection for expensive machinery and gadgets without compromising on quality or durability.

FAQ Section

What is Hydroxypropyl Methylcellulose (HPMC) commonly used for in the construction industry?

HPMC is commonly used in the construction industry for enhancing cement-based materials, tile adhesives, and mortar formulations by improving workability, adhesion, water retention, and preventing slippage.

Why is HPMC preferred in pharmaceutical manufacturing?

HPMC is preferred in pharmaceutical manufacturing for creating vegetarian capsules that enhance drug delivery and bioavailability while catering to consumer demand for clean-label and plant-based products.

How does HPMC benefit the food industry?

In the food industry, HPMC acts as a stabilizer in bakery and dairy formulations and serves as a plant-based emulsifier, enhancing product quality and aligning with consumer preferences for natural ingredients.

What role does HPMC play in personal care and cosmetics?

HPMC is used as a non-toxic thickener in personal care and cosmetics, offering desirable texture, stability, and suitability for sensitive skin, supporting vegan formulations.

How does HPMC contribute to sustainability?

HPMC contributes to sustainability due to its biodegradable properties and ability to reduce environmental impact and carbon footprint, aligning with global efforts towards greener practices.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

CY

CY

IS

IS

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ