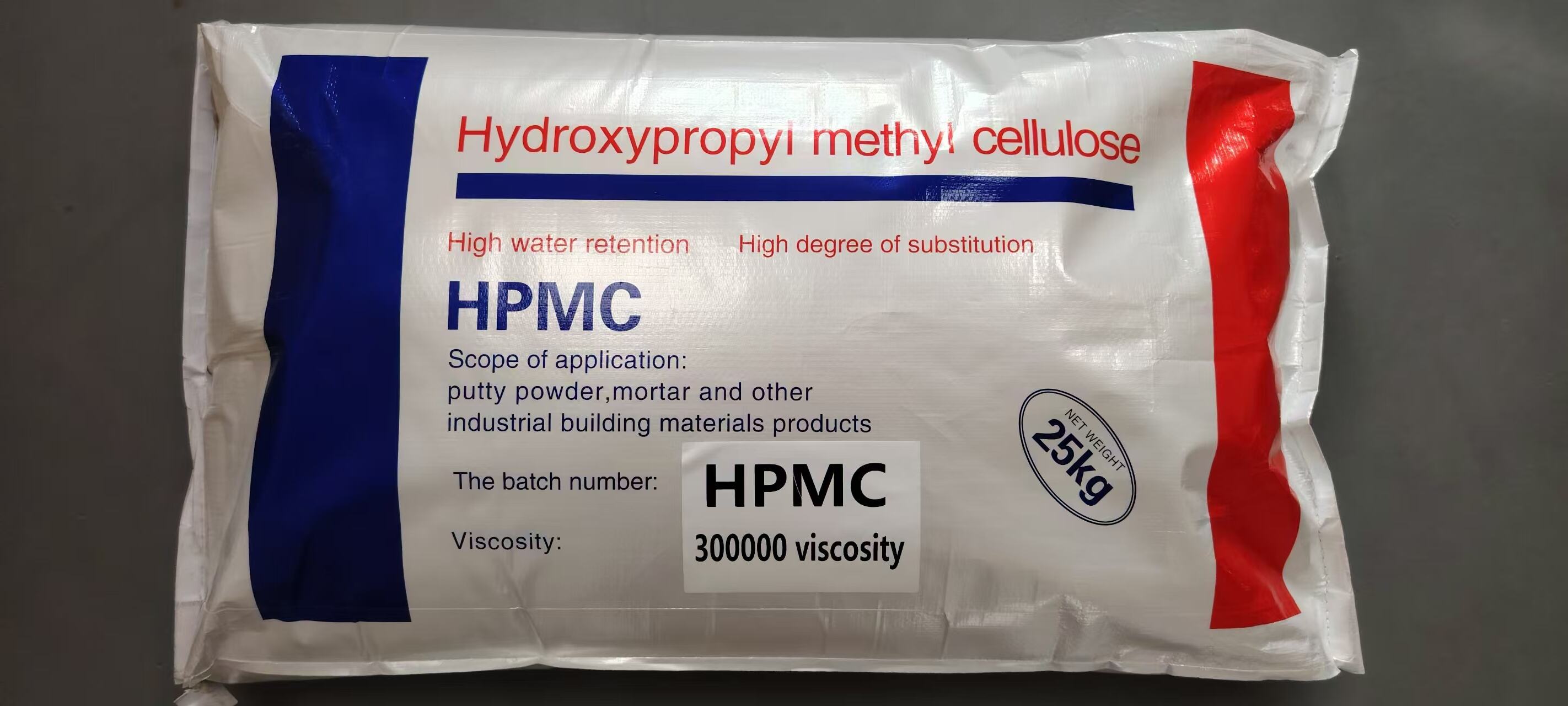

polymer hpmc

Hydroxypropyl methylcellulose (HPMC) is a versatile semi-synthetic polymer derived from cellulose, widely utilized across various industries for its exceptional properties. This remarkable polymer serves as a crucial ingredient in pharmaceutical, construction, food, and personal care applications. In pharmaceutical formulations, HPMC functions as a controlled-release agent, coating material, and binding agent, enabling precise drug delivery systems. The polymer's unique ability to form clear, stable solutions and films makes it invaluable in tablet manufacturing and capsule production. In the construction industry, HPMC acts as a highly effective water-retention agent and rheology modifier in cement-based materials, improving workability and adhesion properties. Its thermal gelation characteristics and film-forming capabilities make it an excellent choice for food applications, where it serves as a thickener, stabilizer, and emulsifier. HPMC's molecular structure can be modified to achieve specific viscosity grades and substitution patterns, allowing manufacturers to tailor its properties for specific applications. The polymer's exceptional stability across various pH levels, temperature resistance, and compatibility with other ingredients have established it as an indispensable component in modern industrial processes. Furthermore, HPMC's biodegradability and non-toxic nature align with growing environmental concerns and safety requirements across industries.