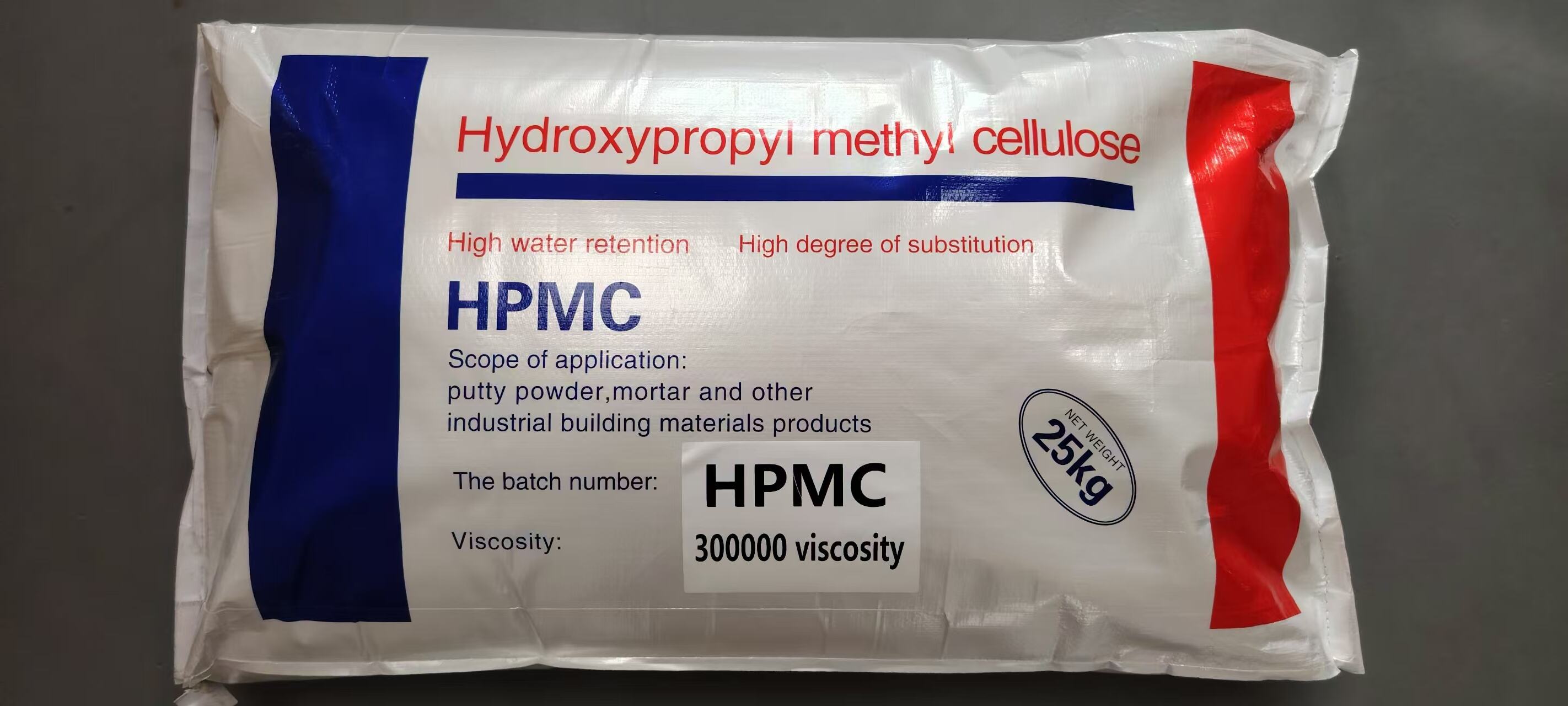

hpmc 615

HPMC 615, or Hydroxypropyl Methylcellulose 615, is a versatile cellulose ether that serves as a crucial ingredient in various industrial applications. This advanced polymer demonstrates exceptional film-forming capabilities and functions as an effective thickening agent, stabilizer, and binder. In the construction industry, HPMC 615 is widely utilized as a cement modifier, enhancing workability and water retention in mortars and concrete mixtures. The compound features a specific viscosity range that makes it particularly suitable for applications requiring precise rheological control. Its molecular structure allows for excellent water solubility while maintaining stability across a broad temperature range. In pharmaceutical applications, HPMC 615 serves as a reliable coating agent for tablets and capsules, providing controlled release properties and improved bioavailability. The material's ability to form clear, flexible films makes it valuable in food packaging and coating applications. Additionally, its non-toxic nature and compliance with various international safety standards make it a preferred choice in food and pharmaceutical industries. HPMC 615's unique chemical properties enable it to maintain consistent performance across different pH levels, making it extremely versatile in various formulation environments.